MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Nominal As Submitted Test Method Fiber Density (g/cm) 1.8 Resin Density (g/cm) 1.28 Composite Density (g/cm3 1.59 1.59-1.61 Fiber Areal Weight (g/m3 280 Fiber Volume (%) 59.6 59-64 Ply Thickness (in) 0.011 0.010-0.011 LAMINATE PROPERTY SUMMARY Classes of data in Strength/Modulus/Poisson's Ratio/Strain-to-Failure order:A=A75,a A55,B B30,b B18,M Mean,I Interim,s Screening,-no data (See Table 1.4.2(c)) 4-26

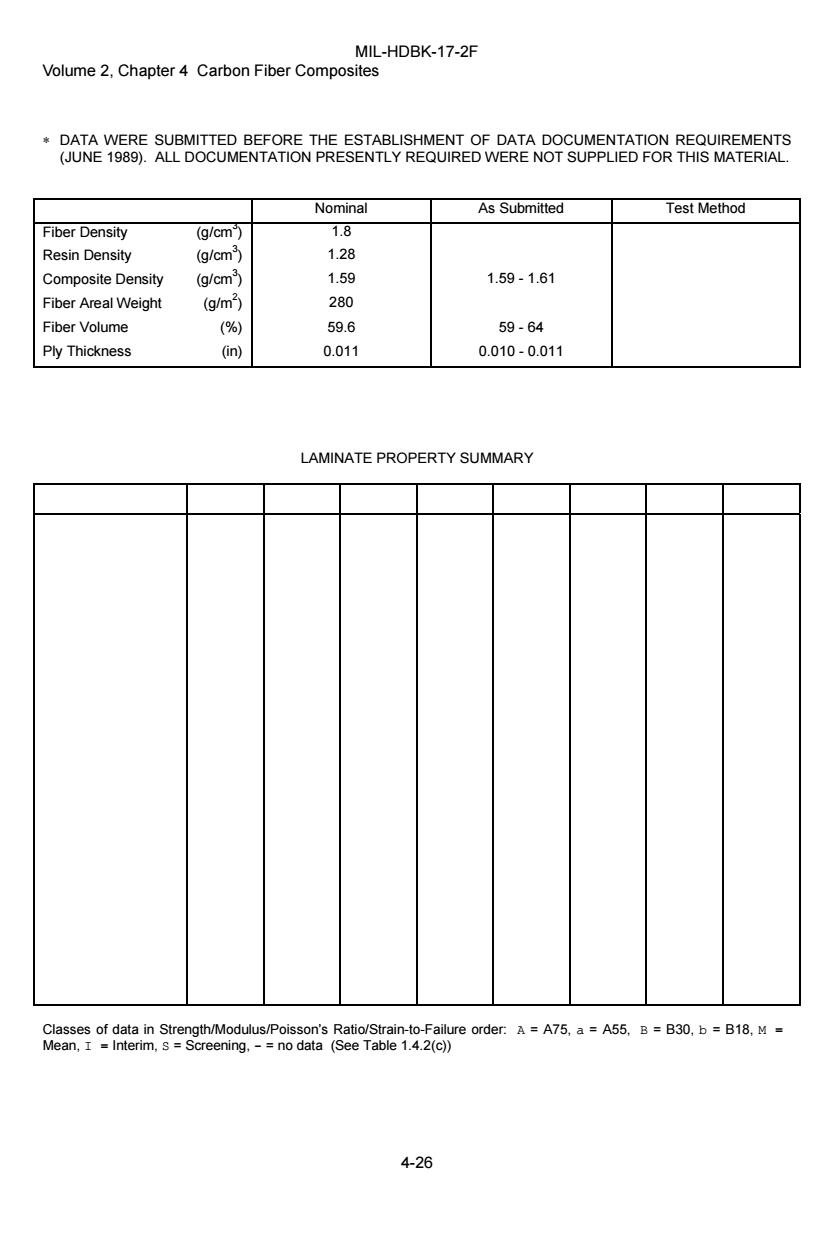

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-26 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Nominal As Submitted Test Method Fiber Density (g/cm3 ) 1.8 Resin Density (g/cm3 ) 1.28 Composite Density (g/cm3 ) 1.59 1.59 - 1.61 Fiber Areal Weight (g/m2 ) 280 Fiber Volume (%) 59.6 59 - 64 Ply Thickness (in) 0.011 0.010 - 0.011 LAMINATE PROPERTY SUMMARY Classes of data in Strength/Modulus/Poisson’s Ratio/Strain-to-Failure order: A = A75, a = A55, B = B30, b = B18, M = Mean, I = Interim, S = Screening, - = no data (See Table 1.4.2(c))

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: Celion 12k/E7K8 unidirectional tape Table 4.2.4(a) C/Ep 280-UT RESIN CONTENT: 29wt% COMP:DENSITY: 1.61g/cm3 Celion E7K8 FIBER VOLUME: 63-64% VOID CONTENT: 0.53-1.0% Tension,1-axis PLY THICKNESS: 0.011in. [0]5 75/A,-65A,75/0.77% TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3039-76 NORMALIZED BY: Fiber volume to 60%(0.011 in.CPT) Temperature (F) 75 -65 75 Moisture Content(%)】 ambient ambient 0.77 Equilibrium at T.RH (1) Source Code 20 20 20 Normalized Measured Normalized Measured Normalized Measured Mean 293 309 281 302 300 314 Minimum 265 285 268 287 292 306 Maximum 317 332 307 330 315 330 c.V.(%) 4.52 4.52 5.44 5.44 3.22 3.60 B-value (2) (2) (2) (2) (2) (2) Fu Distribution Weibull Weibull Normal Normal Normal Normal (ksi) C1 299 316 281 302 300 314 C2 25.6 25.9 15.3 16.4 9.67 10.1 No.Specimens 20 5 5 No.Batches 1 Data Class Screening Screening Screening Mean 20.0 21.1 19.2 20.6 19.0 19.9 Minimum 18.7 20.1 18.6 20.0 18.5 19.4 Maximum 21.9 23.0 20.3 21.8 20.0 21.0 E时 C.V.(%) 4.48 4.25 3.40 3.80 3.22 3.60 (Msi) No.Specimens 20 ⑤ No.Batches Data Class Screening Screening Screening Mean 0.286 0.292 No.Specimens 啦 No.Batches Data Class Screening Screening Mean 14300 14800 Minimum 13500 14200 Maximum 14700 15800 C.V.(%) 3.34 3.87 B-value (2) (2) e Distribution Normal Normal (LE) C 14300 14800 C2 478 573 No.Specimens 5 5 No.Batches 1 1 Data Class Screening Screening (1) Conditioned for 14 days at 160F,85%RH. (2) Basis values are presented only for A and B data classes. 4-27

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-27 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: Celion 12k/E7K8 unidirectional tape Table 4.2.4(a) C/Ep 280-UT RESIN CONTENT: 29 wt% COMP: DENSITY: 1.61 g/cm3 Celion E7K8 FIBER VOLUME: 63-64 % VOID CONTENT: 0.53-1.0% Tension, 1-axis PLY THICKNESS: 0.011 in. [0]5 75/A, -65/A, 75/0.77% TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3039-76 NORMALIZED BY: Fiber volume to 60% (0.011 in. CPT) Temperature (°F) 75 -65 75 Moisture Content (%) ambient ambient 0.77 Equilibrium at T, RH (1) Source Code 20 20 20 Normalized Measured Normalized Measured Normalized Measured Mean 293 309 281 302 300 314 Minimum 265 285 268 287 292 306 Maximum 317 332 307 330 315 330 C.V.(%) 4.52 4.52 5.44 5,44 3.22 3.60 B-value (2) (2) (2) (2) (2) (2) Ftu 1 Distribution Weibull Weibull Normal Normal Normal Normal (ksi) C1 299 316 281 302 300 314 C2 25.6 25.9 15.3 16.4 9.67 10.1 No. Specimens 20 5 5 No. Batches 1 1 1 Data Class Screening Screening Screening Mean 20.0 21.1 19.2 20.6 19.0 19.9 Minimum 18.7 20.1 18.6 20.0 18.5 19.4 Maximum 21.9 23.0 20.3 21.8 20.0 21.0 Et 1 C.V.(%) 4.48 4.25 3.40 3.80 3.22 3.60 (Msi) No. Specimens 20 5 5 No. Batches 1 1 1 Data Class Screening Screening Screening Mean 0.286 0.292 No. Specimens 5 5 ν 12 t No. Batches 1 1 Data Class Screening Screening Mean 14300 14800 Minimum 13500 14200 Maximum 14700 15800 C.V.(%) 3.34 3.87 B-value (2) (2) ε 1 tu Distribution Normal Normal (µε) C1 14300 14800 C2 478 573 No. Specimens 5 5 No. Batches 1 1 Data Class Screening Screening (1) Conditioned for 14 days at 160°F, 85% RH. (2) Basis values are presented only for A and B data classes

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: Celion 12k/E7K8 unidirectional tape Table 4.2.4(b) C/Ep 280-UT RESIN CONTENT: 29wt% COMP:DENSITY: 1.61g/cm3 Celion E7K8 FIBER VOLUME: 63-64% VOID CONTENT: 0.53-1.0% Tension,1-axis PLY THICKNESS: 0.011in. [0]5 18070.77% TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3039-76 NORMALIZED BY: Fiber volume to 60%(0.011 in.CPT) Temperature (F) 180 Moisture Content(%)】 0.77 Equilibrium at T.RH (1) Source Code 20 Normalized Measured Normalized Measured Normalized Measured Mean 293 311 Minimum 269 286 Maximum 316 335 C.V.(%) 6.43 7.19 B-value (2) (2) Fu Distribution Normal Normal (ksi) C1 293 311 C2 18.9 20.0 No.Specimens 5 No.Batches 1 Data Class Screening Mean 19.8 21.0 Minimum 19.4 20.6 Maximum 20.1 21.4 E时 C.V.(%) 1.61 1.81 (Msi) No.Specimens 5 No.Batches Data Class Screening Mean 0.322 No.Specimens 啦 No.Batches Data Class Screening Mean 13800 Minimum 12300 Maximum 15400 C.V.(%) 10.4 B-value (2) e Distribution Normal (LE) Ci 13800 C2 1440 No.Specimens 5 No.Batches 1 Data Class Screening (1) Conditioned for 14 days at 160F,85%RH. (2) Basis values are presented only for A and B data classes. 4-28

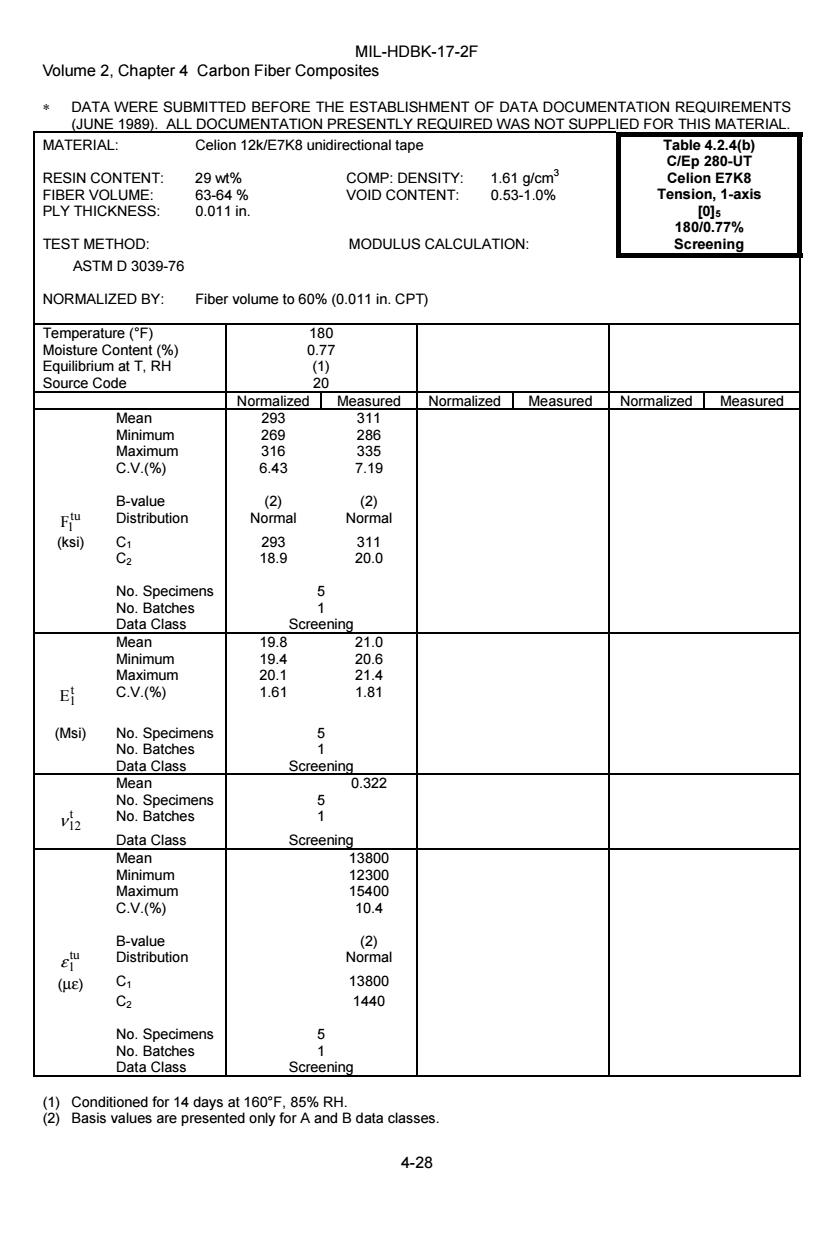

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-28 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: Celion 12k/E7K8 unidirectional tape Table 4.2.4(b) C/Ep 280-UT RESIN CONTENT: 29 wt% COMP: DENSITY: 1.61 g/cm3 Celion E7K8 FIBER VOLUME: 63-64 % VOID CONTENT: 0.53-1.0% Tension, 1-axis PLY THICKNESS: 0.011 in. [0]5 180/0.77% TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3039-76 NORMALIZED BY: Fiber volume to 60% (0.011 in. CPT) Temperature (°F) 180 Moisture Content (%) 0.77 Equilibrium at T, RH (1) Source Code 20 Normalized Measured Normalized Measured Normalized Measured Mean 293 311 Minimum 269 286 Maximum 316 335 C.V.(%) 6.43 7.19 B-value (2) (2) Ftu 1 Distribution Normal Normal (ksi) C1 293 311 C2 18.9 20.0 No. Specimens 5 No. Batches 1 Data Class Screening Mean 19.8 21.0 Minimum 19.4 20.6 Maximum 20.1 21.4 Et 1 C.V.(%) 1.61 1.81 (Msi) No. Specimens 5 No. Batches 1 Data Class Screening Mean 0.322 No. Specimens 5 ν 12 t No. Batches 1 Data Class Screening Mean 13800 Minimum 12300 Maximum 15400 C.V.(%) 10.4 B-value (2) ε 1 tu Distribution Normal (µε) C1 13800 C2 1440 No. Specimens 5 No. Batches 1 Data Class Screening (1) Conditioned for 14 days at 160°F, 85% RH. (2) Basis values are presented only for A and B data classes

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: Celion 12k/E7K8 unidirectional tape Table 4.2.4(c) C/Ep 280-UT RESIN CONTENT: 31-33wt% COMP:DENSITY:1.59-1.60 g/cm3 Celion/E7K8 FIBER VOLUME: 59-61% VOID CONTENT: 0.68-0.74% Tension,2-axis PLY THICKNESS: 0.011in. [90]12 75/A TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3039-76 NORMALIZED BY: Not normalized Temperature (F) 75 Moisture Content(%)】 ambient Equilibrium at T.RH Source Code 20 Mean 6.00 Minimum 5.21 Maximum 6.89 C.V.(%) 8.79 B-value (1) Fu Distribution Weibull (ksi) C1 6.24 C2 12.6 No.Specimens 20 No.Batches 1 Data Class Screening Mean 1.28 Minimum 1.19 Maximum 1.36 E吃 C.V.(%) 4.52 (Msi) No.Specimens 20 No.Batches 1 Data Class Screening Mean No.Specimens 吃1 No.Batches Data Class Mean Minimum Maximum C.V.(%) B-value e Distribution (LE) C C2 No.Specimens No.Batches Data Class (1)Basis values are presented only for A and B data classes. 4-29

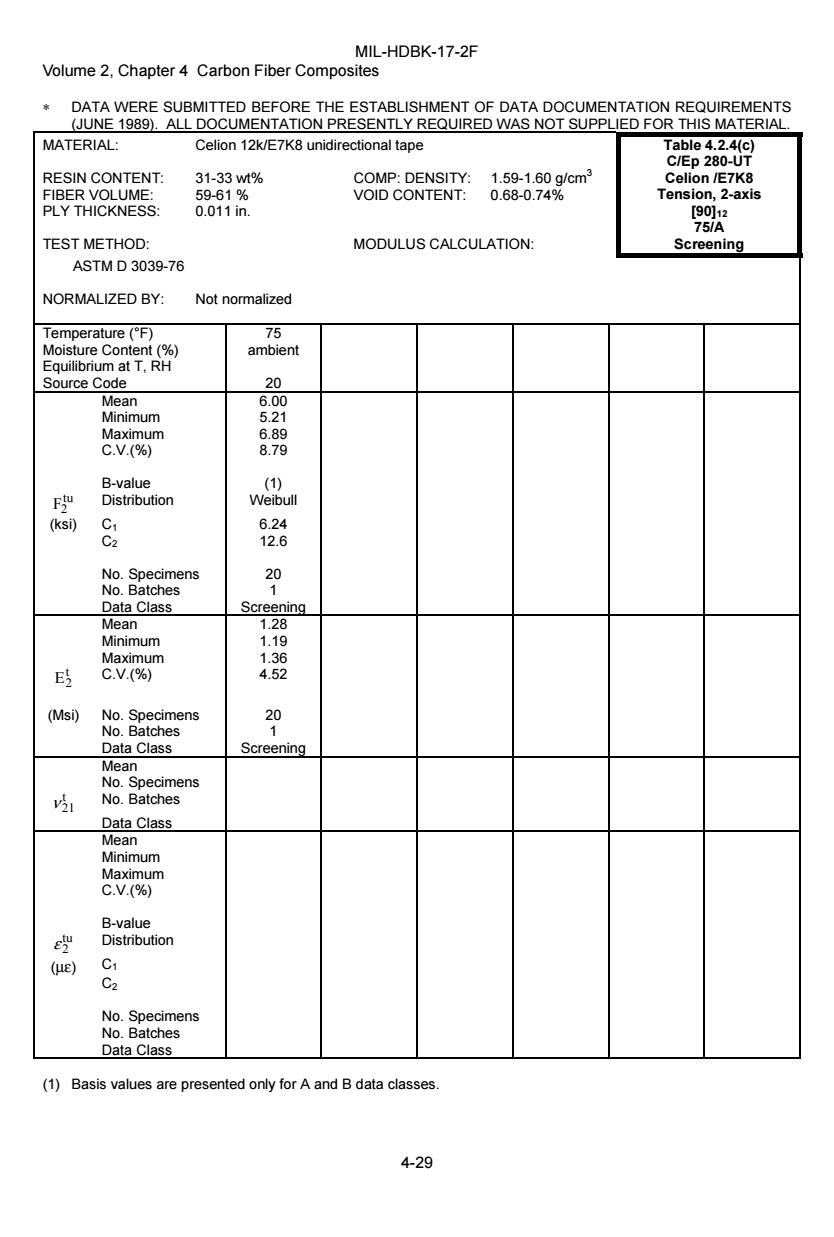

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-29 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: Celion 12k/E7K8 unidirectional tape Table 4.2.4(c) C/Ep 280-UT RESIN CONTENT: 31-33 wt% COMP: DENSITY: 1.59-1.60 g/cm3 Celion /E7K8 FIBER VOLUME: 59-61 % VOID CONTENT: 0.68-0.74% Tension, 2-axis PLY THICKNESS: 0.011 in. [90]12 75/A TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3039-76 NORMALIZED BY: Not normalized Temperature (°F) 75 Moisture Content (%) ambient Equilibrium at T, RH Source Code 20 Mean 6.00 Minimum 5.21 Maximum 6.89 C.V.(%) 8.79 B-value (1) Ftu 2 Distribution Weibull (ksi) C1 6.24 C2 12.6 No. Specimens 20 No. Batches 1 Data Class Screening Mean 1.28 Minimum 1.19 Maximum 1.36 Et 2 C.V.(%) 4.52 (Msi) No. Specimens 20 No. Batches 1 Data Class Screening Mean No. Specimens ν 21 t No. Batches Data Class Mean Minimum Maximum C.V.(%) B-value ε 2 tu Distribution (µε) C1 C2 No. Specimens No. Batches Data Class (1) Basis values are presented only for A and B data classes

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: Celion 12k/E7K8 unidirectional tape Table 4.2.4(d) C/Ep 280-UT RESIN CONTENT: 29-30wt% COMP:DENSITY: 1.60-1.61g/cm3 Celion E7K8 FIBER VOLUME: 62-64% VOID CONTENT: 0.78-0.79% Compression,1-axis PLY THICKNESS: 0.010in. [0]5 75/A,-65A,75/0.77% TEST METHOD: MODULUS CALCULATION: Screening SACMA SRM 1-88 NORMALIZED BY: Fiber volume to 60%(0.011 in.CPT) Temperature (F) 75 -65 75 Moisture Content(%) ambient ambient 0.77 Equilibrium at T.RH (1) Source Code 20 20 20 Normalized Measured Normalized Measured Normalized Measured Mean 206 213 221 229 207 214 Minimum 171 177 198 205 198 205 Maximum 247 255 267 276 219 227 C.V.(%) 8.62 8.62 12.2 12.2 5.06 5.06 B-value (2) (2) (2) (2) (2) (2) Fcu Distribution Weibull Weibull Normal Normal Normal Normal (ksi) C1 214 221 221 228 207 214 C2 12.1 12.1 27.0 28.0 10.5 10.8 No.Specimens 20 6 5 No.Batches 1 1 Data Class Screening Screening Screening Mean 19.9 21.1 22.9 24.3 21.6 22.3 Minimum 18.1 19.2 20.8 22.0 20.2 21.0 Maximum 21.7 22.3 23.8 25.1 22.8 23.6 E C.V.(%) 4.95 5.08 5.28 5.90 5.25 5.86 (Msi) No.Specimens 20 ⑤ No.Batches Data Class Screening Screening Screening Mean No.Specimens Vi2 No.Batches Data Class Mean 11200 9870 Minimum 10800 9210 Maximum 11800 10600 C.V.(%) 3.59 5.32 B-value (2) (2) ecu Distribution Normal Normal (LE) Ci 11200 9870 C2 401 526 No.Specimens 5 5 No.Batches 1 1 Data Class Screening Screening (1) Conditioned for 14 days at 160F,85%RH. (2) Basis values are presented only for A and B data classes. 4-30

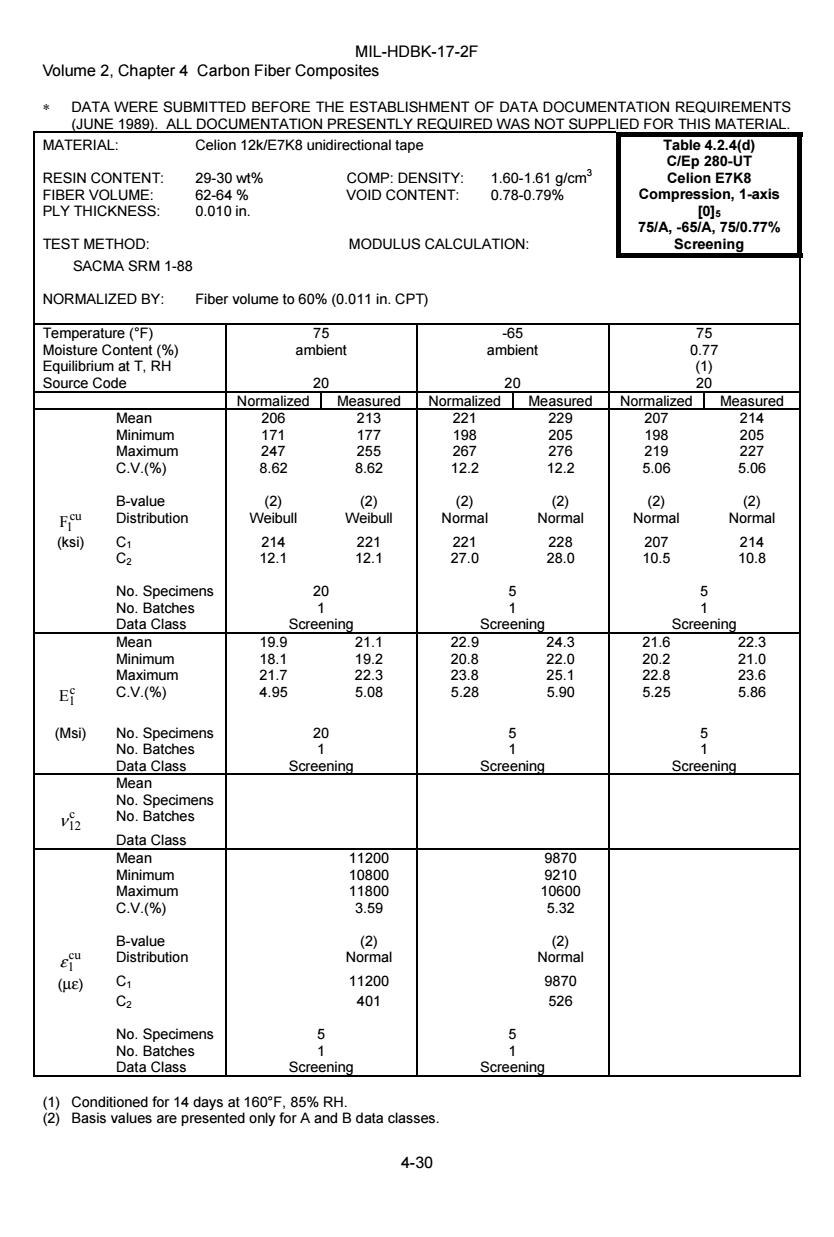

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-30 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: Celion 12k/E7K8 unidirectional tape Table 4.2.4(d) C/Ep 280-UT RESIN CONTENT: 29-30 wt% COMP: DENSITY: 1.60-1.61 g/cm3 Celion E7K8 FIBER VOLUME: 62-64 % VOID CONTENT: 0.78-0.79% Compression, 1-axis PLY THICKNESS: 0.010 in. [0]5 75/A, -65/A, 75/0.77% TEST METHOD: MODULUS CALCULATION: Screening SACMA SRM 1-88 NORMALIZED BY: Fiber volume to 60% (0.011 in. CPT) Temperature (°F) 75 -65 75 Moisture Content (%) ambient ambient 0.77 Equilibrium at T, RH (1) Source Code 20 20 20 Normalized Measured Normalized Measured Normalized Measured Mean 206 213 221 229 207 214 Minimum 171 177 198 205 198 205 Maximum 247 255 267 276 219 227 C.V.(%) 8.62 8.62 12.2 12.2 5.06 5.06 B-value (2) (2) (2) (2) (2) (2) Fcu 1 Distribution Weibull Weibull Normal Normal Normal Normal (ksi) C1 214 221 221 228 207 214 C2 12.1 12.1 27.0 28.0 10.5 10.8 No. Specimens 20 5 5 No. Batches 1 1 1 Data Class Screening Screening Screening Mean 19.9 21.1 22.9 24.3 21.6 22.3 Minimum 18.1 19.2 20.8 22.0 20.2 21.0 Maximum 21.7 22.3 23.8 25.1 22.8 23.6 Ec 1 C.V.(%) 4.95 5.08 5.28 5.90 5.25 5.86 (Msi) No. Specimens 20 5 5 No. Batches 1 1 1 Data Class Screening Screening Screening Mean No. Specimens ν 12 c No. Batches Data Class Mean 11200 9870 Minimum 10800 9210 Maximum 11800 10600 C.V.(%) 3.59 5.32 B-value (2) (2) ε 1 cu Distribution Normal Normal (µε) C1 11200 9870 C2 401 526 No. Specimens 5 5 No. Batches 1 1 Data Class Screening Screening (1) Conditioned for 14 days at 160°F, 85% RH. (2) Basis values are presented only for A and B data classes