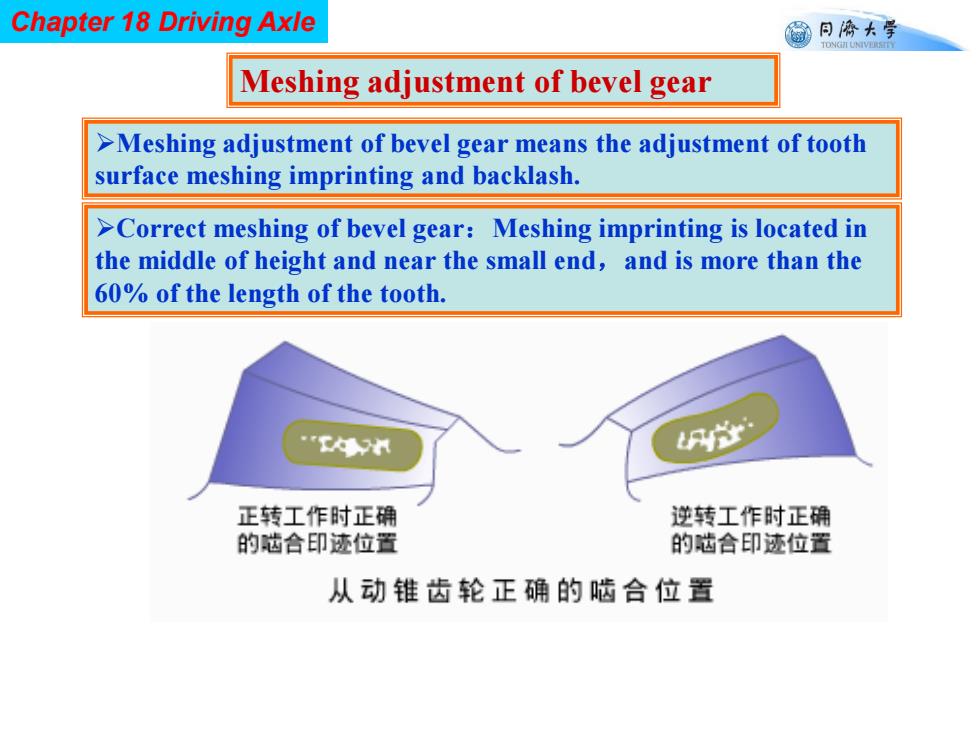

Chapter 18 Driving Axle 窗同傍大学 TONGII UNIVERSTTY Meshing adjustment of bevel gear >Meshing adjustment of bevel gear means the adjustment of tooth surface meshing imprinting and backlash. >Correct meshing of bevel gear:Meshing imprinting is located in the middle of height and near the small end,and is more than the 60%of the length of the tooth. " Y 正转工作时正确 逆转工作时正确 的啮合印迹位置 的选合印迹位置 从动锥齿轮正确的啮合位置

Chapter 18 Driving Axle Correct meshing of bevel gear:Meshing imprinting is located in the middle of height and near the small end,and is more than the 60% of the length of the tooth. Meshing adjustment of bevel gear Meshing adjustment of bevel gear means the adjustment of tooth surface meshing imprinting and backlash

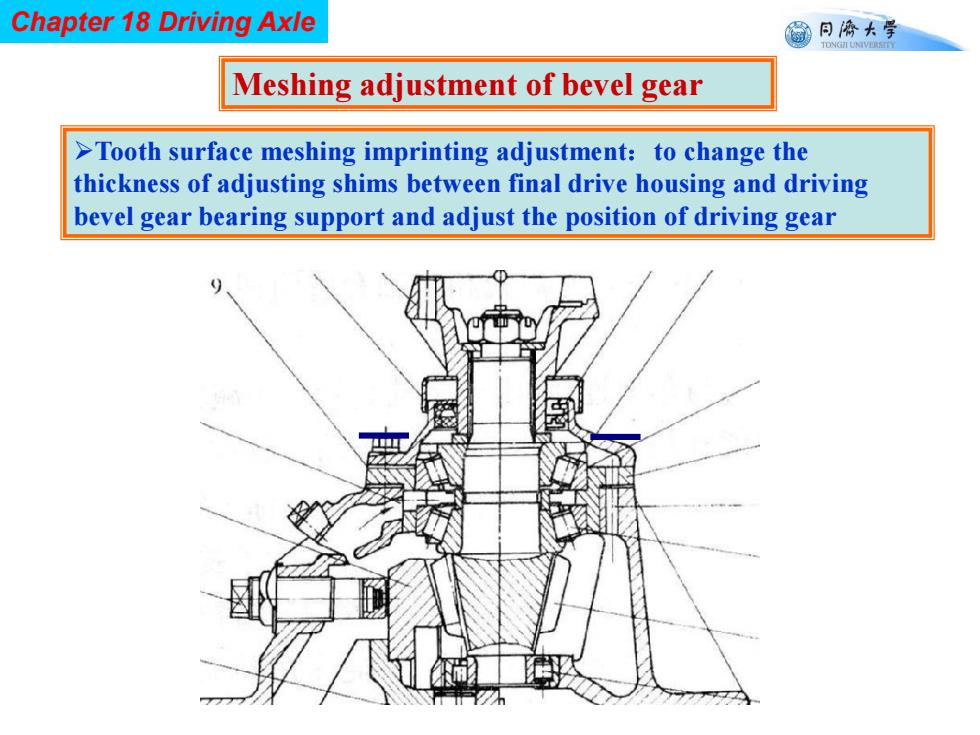

Chapter 18 Driving Axle 同©大学 TONGII UNIVERSTTY Meshing adjustment of bevel gear >Tooth surface meshing imprinting adjustment:to change the thickness of adjusting shims between final drive housing and driving bevel gear bearing support and adjust the position of driving gear

Chapter 18 Driving Axle Tooth surface meshing imprinting adjustment:to change the thickness of adjusting shims between final drive housing and driving bevel gear bearing support and adjust the position of driving gear Meshing adjustment of bevel gear

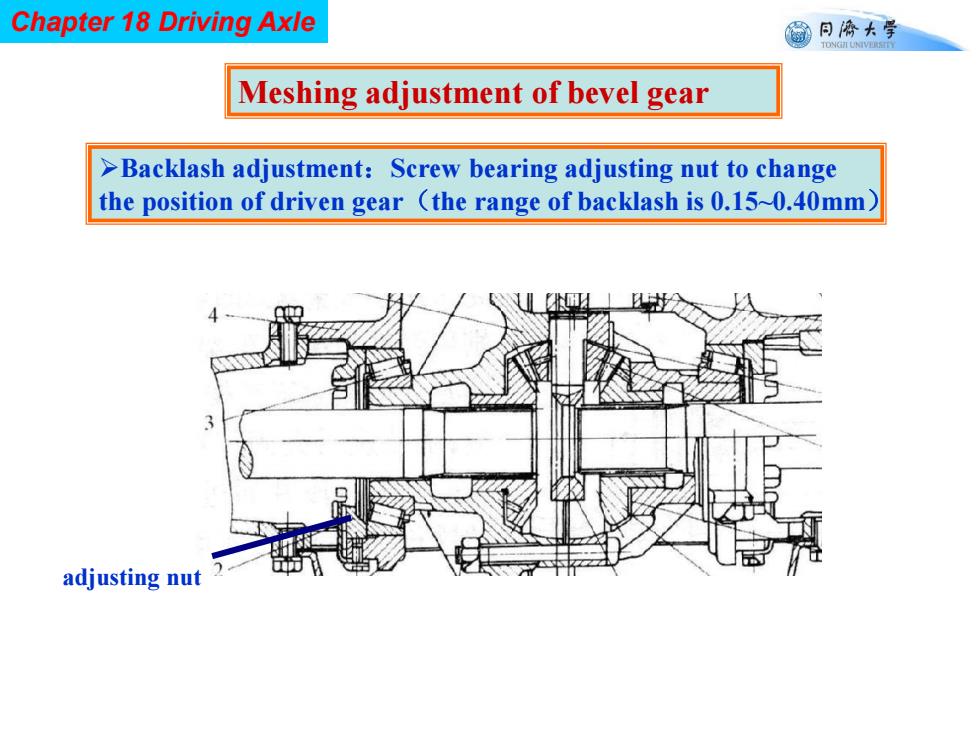

Chapter 18 Driving Axle 窗月桥大学 TONGII UNIVERSTTY Meshing adjustment of bevel gear >Backlash adjustment:Screw bearing adjusting nut to change the position of driven gear (the range of backlash is 0.15~0.40mm) adjusting nut

Chapter 18 Driving Axle Backlash adjustment:Screw bearing adjusting nut to change the position of driven gear(the range of backlash is 0.15~0.40mm) Meshing adjustment of bevel gear adjusting nut

Chapter 18 Driving Axle 窗月桥大学 TONGII UNIVERSTTY Meshing adjustment of bevel gear Adjusting nut >In order to keep the adjusted differential tapered roller bearing a good tightness,the number of ring screwed into the adjustment nut should be equal to the other end of the ring nut; >Preload adjustment of tapered roller bearing must be carried out before the gear adjustment; >Ensure correct meshing and backlash by adjusting the thickness of adjusting shims and the position of adjusting nut

Chapter 18 Driving Axle Meshing adjustment of bevel gear In order to keep the adjusted differential tapered roller bearing a good tightness,the number of ring screwed into the adjustment nut should be equal to the other end of the ring nut; Preload adjustment of tapered roller bearing must be carried out before the gear adjustment; Adjusting nut Ensure correct meshing and backlash by adjusting the thickness of adjusting shims and the position of adjusting nut

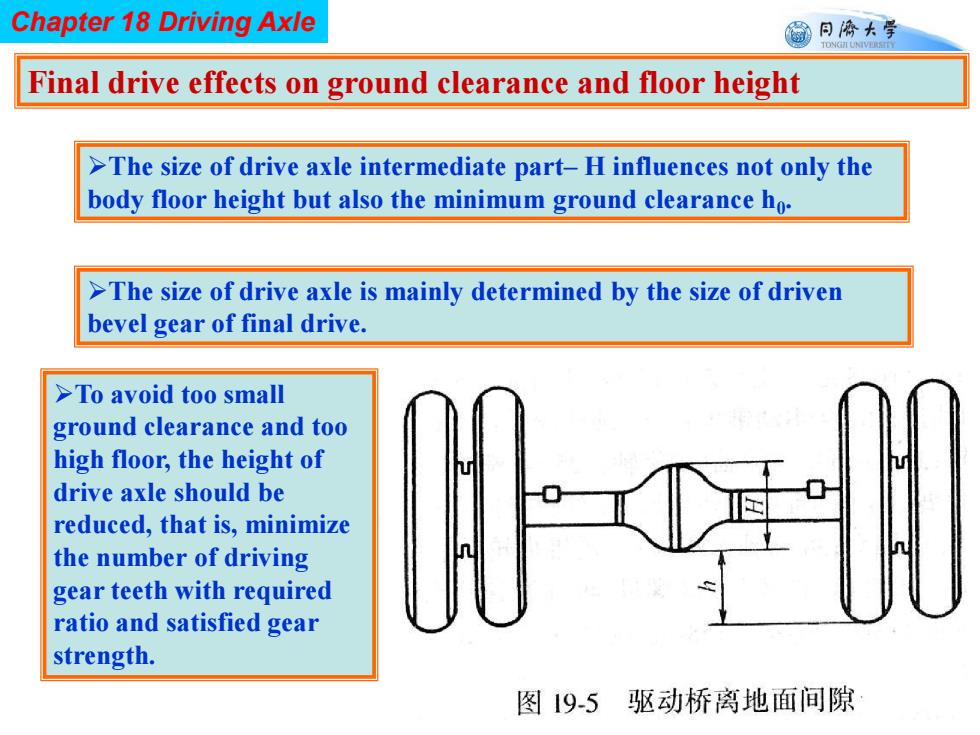

Chapter 18 Driving Axle 同©大学 TONGII UNIVERSTTY Final drive effects on ground clearance and floor height >The size of drive axle intermediate part-H influences not only the body floor height but also the minimum ground clearance ho. >The size of drive axle is mainly determined by the size of driven bevel gear of final drive. >To avoid too small ground clearance and too high floor,the height of drive axle should be reduced,that is,minimize the number of driving n gear teeth with required ratio and satisfied gear strength. 图19-5驱动桥离地面间隙

Chapter 18 Driving Axle Final drive effects on ground clearance and floor height The size of drive axle intermediate part– H influences not only the body floor height but also the minimum ground clearance h0 . To avoid too small ground clearance and too high floor, the height of drive axle should be reduced, that is, minimize the number of driving gear teeth with required ratio and satisfied gear strength. The size of drive axle is mainly determined by the size of driven bevel gear of final drive