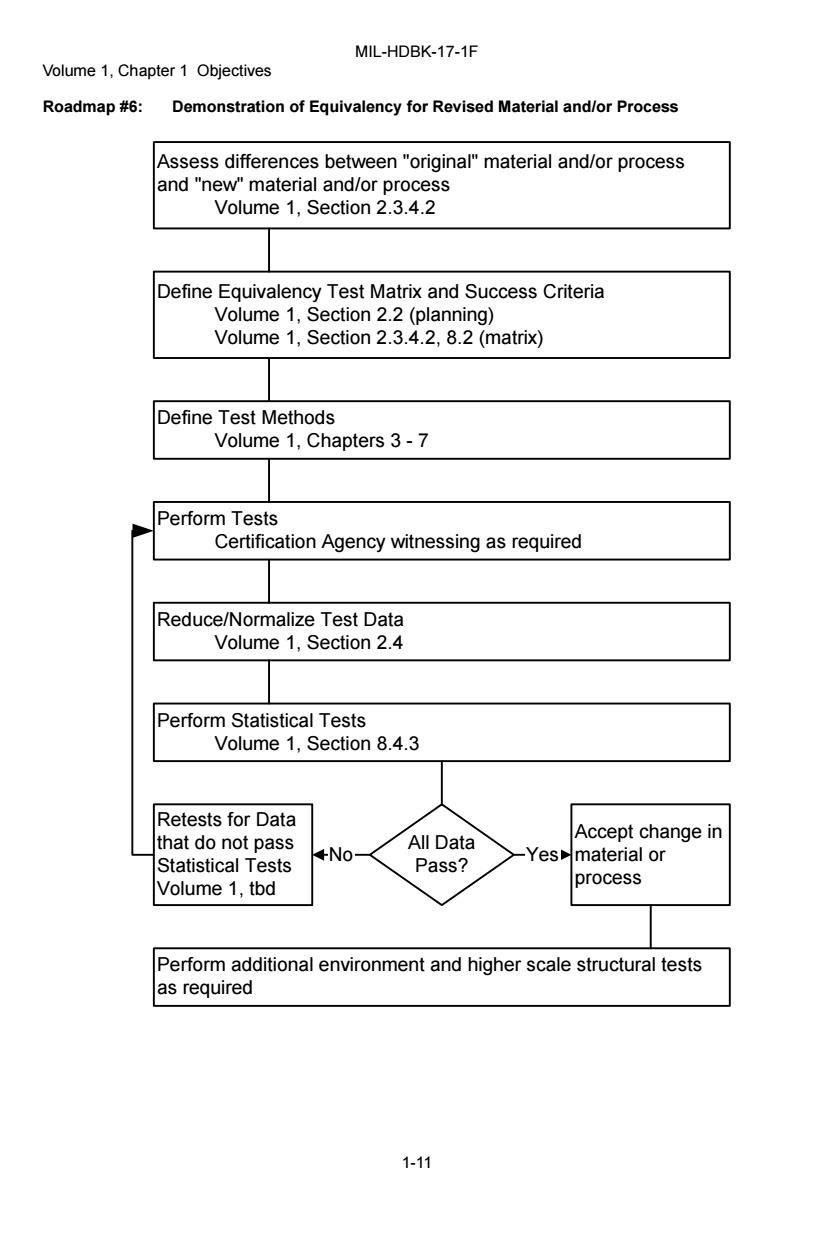

MIL-HDBK-17-1F Volume 1,Chapter 1 Objectives Roadmap #6: Demonstration of Equivalency for Revised Material and/or Process Assess differences between "original"material and/or process and "new"material and/or process Volume 1,Section 2.3.4.2 Define Equivalency Test Matrix and Success Criteria Volume 1,Section 2.2(planning) Volume 1,Section 2.3.4.2,8.2(matrix) Define Test Methods Volume 1,Chapters 3-7 Perform Tests Certification Agency witnessing as required Reduce/Normalize Test Data Volume 1,Section 2.4 Perform Statistical Tests Volume 1,Section 8.4.3 Retests for Data that do not pass All Data Accept change in Statistical Tests +No Pass? -Yesmaterial or Volume 1,tbd process Perform additional environment and higher scale structural tests as required 1-11

MIL-HDBK-17-1F Volume 1, Chapter 1 Objectives 1-11 Roadmap #6: Demonstration of Equivalency for Revised Material and/or Process Define Equivalency Test Matrix and Success Criteria Volume 1, Section 2.2 (planning) Volume 1, Section 2.3.4.2, 8.2 (matrix) Define Test Methods Volume 1, Chapters 3 - 7 Perform Tests Certification Agency witnessing as required Reduce/Normalize Test Data Volume 1, Section 2.4 Perform Statistical Tests Volume 1, Section 8.4.3 Assess differences between "original" material and/or process and "new" material and/or process Volume 1, Section 2.3.4.2 All Data Pass? Retests for Data that do not pass Statistical Tests Volume 1, tbd Accept change in material or process No Yes Perform additional environment and higher scale structural tests as required

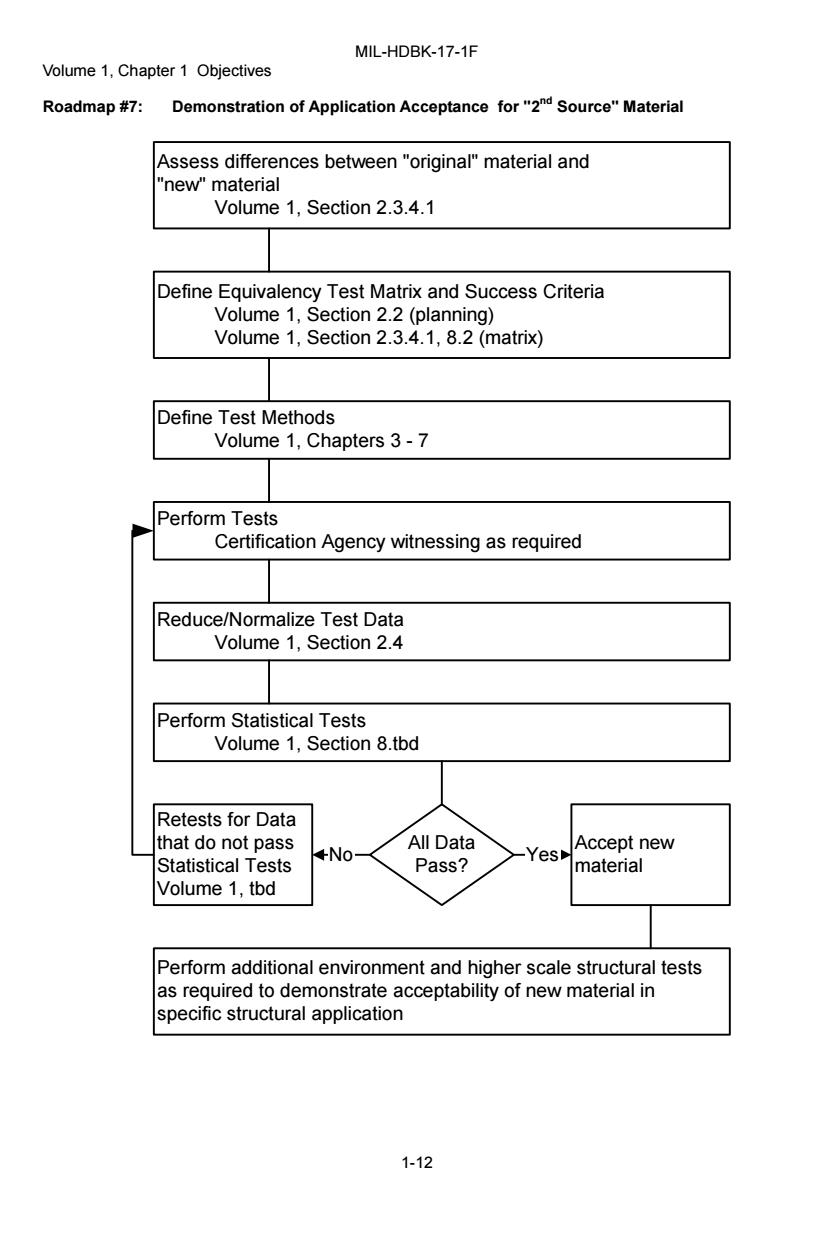

MIL-HDBK-17-1F Volume 1,Chapter 1 Objectives Roadmap #7: Demonstration of Application Acceptance for"2d Source"Material Assess differences between "original"material and new"material Volume 1,Section 2.3.4.1 Define Equivalency Test Matrix and Success Criteria Volume 1,Section 2.2(planning) Volume 1,Section 2.3.4.1,8.2(matrix) Define Test Methods Volume 1,Chapters 3-7 Perform Tests Certification Agency witnessing as required Reduce/Normalize Test Data Volume 1,Section 2.4 Perform Statistical Tests Volume 1.Section 8.tbd Retests for Data that do not pass All Data +No >-Yes Accept new Statistical Tests Pass? material Volume 1,tbd Perform additional environment and higher scale structural tests as required to demonstrate acceptability of new material in specific structural application 1-12

MIL-HDBK-17-1F Volume 1, Chapter 1 Objectives 1-12 Roadmap #7: Demonstration of Application Acceptance for "2nd Source" Material Define Equivalency Test Matrix and Success Criteria Volume 1, Section 2.2 (planning) Volume 1, Section 2.3.4.1, 8.2 (matrix) Define Test Methods Volume 1, Chapters 3 - 7 Perform Tests Certification Agency witnessing as required Reduce/Normalize Test Data Volume 1, Section 2.4 Perform Statistical Tests Volume 1, Section 8.tbd Assess differences between "original" material and "new" material Volume 1, Section 2.3.4.1 All Data Pass? Retests for Data that do not pass Statistical Tests Volume 1, tbd Accept new material No Yes Perform additional environment and higher scale structural tests as required to demonstrate acceptability of new material in specific structural application

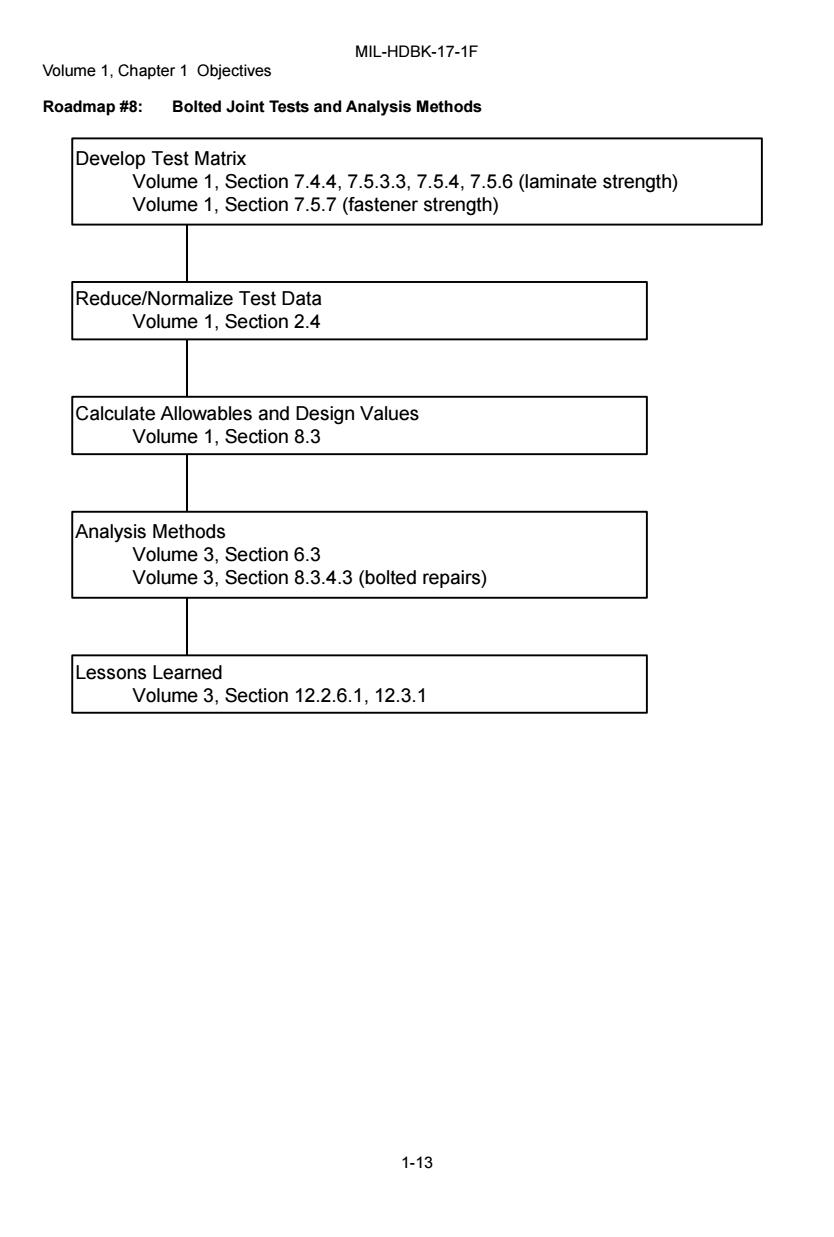

MIL-HDBK-17-1F Volume 1,Chapter 1 Objectives Roadmap #8:Bolted Joint Tests and Analysis Methods Develop Test Matrix Volume 1,Section 7.4.4,7.5.3.3,7.5.4,7.5.6(laminate strength) Volume 1,Section 7.5.7(fastener strength) Reduce/Normalize Test Data Volume 1,Section 2.4 Calculate Allowables and Design Values Volume 1,Section 8.3 Analysis Methods Volume 3,Section 6.3 Volume 3,Section 8.3.4.3(bolted repairs) Lessons Learned Volume 3,Section 12.2.6.1,12.3.1 1-13

MIL-HDBK-17-1F Volume 1, Chapter 1 Objectives 1-13 Roadmap #8: Bolted Joint Tests and Analysis Methods Develop Test Matrix Volume 1, Section 7.4.4, 7.5.3.3, 7.5.4, 7.5.6 (laminate strength) Volume 1, Section 7.5.7 (fastener strength) Reduce/Normalize Test Data Volume 1, Section 2.4 Calculate Allowables and Design Values Volume 1, Section 8.3 Analysis Methods Volume 3, Section 6.3 Volume 3, Section 8.3.4.3 (bolted repairs) Lessons Learned Volume 3, Section 12.2.6.1, 12.3.1

MIL-HDBK-17-1F Volume 1,Chapter 1 Objectives Roadmap #9: Bonded Joint Tests and Analysis Methods Reference Sections Volume 1,Chapter 4 Volume 3,Chapter 2 Develop Material and Process Specifications Volume 3,Section 2.11 Develop Test Matrix Volume 1,Section 7.6.2 Volume 1,Section 6.7.8 Calculate Allowables and Design Values Volume 1,Section 8.3 Analysis Methods Volume 3,Section 6.2(Bonded Joints) Volume 3,Section 7.7.4.2(Disbond Growth) Volume 3,Section 7.8.4.2(Disbonds) Volume 3,Section 8.3.4.4(Bonded Repairs) Lessons Learned Volume 3,Section 12.2.6.2,12.3.1.3 1-14

MIL-HDBK-17-1F Volume 1, Chapter 1 Objectives 1-14 Roadmap #9: Bonded Joint Tests and Analysis Methods Develop Test Matrix Volume 1, Section 7.6.2 Volume 1, Section 6.7.8 Calculate Allowables and Design Values Volume 1, Section 8.3 Analysis Methods Volume 3, Section 6.2 (Bonded Joints) Volume 3, Section 7.7.4.2 (Disbond Growth) Volume 3, Section 7.8.4.2 (Disbonds) Volume 3, Section 8.3.4.4 (Bonded Repairs) Lessons Learned Volume 3, Section 12.2.6.2, 12.3.1.3 Reference Sections Volume 1, Chapter 4 Volume 3, Chapter 2 Develop Material and Process Specifications Volume 3, Section 2.11

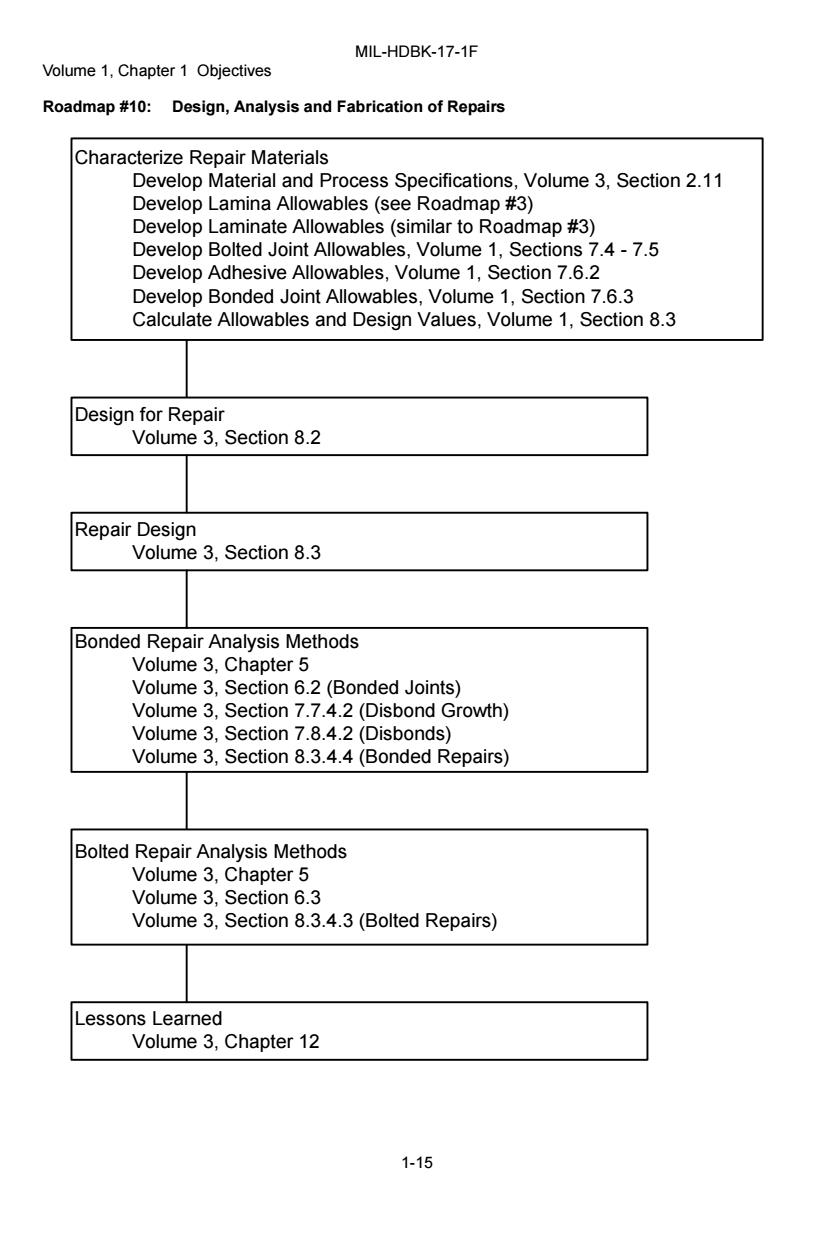

MIL-HDBK-17-1F Volume 1,Chapter 1 Objectives Roadmap #10:Design,Analysis and Fabrication of Repairs Characterize Repair Materials Develop Material and Process Specifications,Volume 3,Section 2.11 Develop Lamina Allowables (see Roadmap #3) Develop Laminate Allowables(similar to Roadmap #3) Develop Bolted Joint Allowables,Volume 1,Sections 7.4-7.5 Develop Adhesive Allowables,Volume 1,Section 7.6.2 Develop Bonded Joint Allowables,Volume 1,Section 7.6.3 Calculate Allowables and Design Values,Volume 1,Section 8.3 Design for Repair Volume 3,Section 8.2 Repair Design Volume 3,Section 8.3 Bonded Repair Analysis Methods Volume 3,Chapter 5 Volume 3,Section 6.2(Bonded Joints) Volume 3,Section 7.7.4.2(Disbond Growth) Volume 3,Section 7.8.4.2(Disbonds) Volume 3,Section 8.3.4.4(Bonded Repairs) Bolted Repair Analysis Methods Volume 3,Chapter 5 Volume 3,Section 6.3 Volume 3,Section 8.3.4.3(Bolted Repairs) essons Learned Volume 3,Chapter 12 1-15

MIL-HDBK-17-1F Volume 1, Chapter 1 Objectives 1-15 Roadmap #10: Design, Analysis and Fabrication of Repairs Bonded Repair Analysis Methods Volume 3, Chapter 5 Volume 3, Section 6.2 (Bonded Joints) Volume 3, Section 7.7.4.2 (Disbond Growth) Volume 3, Section 7.8.4.2 (Disbonds) Volume 3, Section 8.3.4.4 (Bonded Repairs) Lessons Learned Volume 3, Chapter 12 Characterize Repair Materials Develop Material and Process Specifications, Volume 3, Section 2.11 Develop Lamina Allowables (see Roadmap #3) Develop Laminate Allowables (similar to Roadmap #3) Develop Bolted Joint Allowables, Volume 1, Sections 7.4 - 7.5 Develop Adhesive Allowables, Volume 1, Section 7.6.2 Develop Bonded Joint Allowables, Volume 1, Section 7.6.3 Calculate Allowables and Design Values, Volume 1, Section 8.3 Bolted Repair Analysis Methods Volume 3, Chapter 5 Volume 3, Section 6.3 Volume 3, Section 8.3.4.3 (Bolted Repairs) Design for Repair Volume 3, Section 8.2 Repair Design Volume 3, Section 8.3