Contributors Chapter Contributors 1.Introduction and Overview A.A.Baker* 2.Basic Principles of Fiber Composite A.A.Baker Materials A.Rachinger* 3.Fibers for Polymer-Matrix Composites A.A.Baker K.H.Leong" 4.Polymeric Matrix Materials A.A.Baker J.Hodgkin M.Hou' 5.Component Form and Manufacture A.A.Baker R.Paton' T.Kruckenburgt P.Falzon' I.Crouch' S.Dutton M.Hou X.Liu W.Hilliert 6.Structural Analysis B.Hoskin* D.Kellys R.Lis 7.Mechanical Property Measurement M.Bannistert A.A.Baker A.Garg A.A.Kharibi** Y.W.Mai* Affiliations at the time of drafting: *DSTO,Dept of Defence,Commonwealth of Australia CRC-ACS Ltd. Department of Molecular Science,CSIRO University of New South Wales "Hawker De Havilland Aerospace Ltd. ◆*University of Sydney

Contributors Chapter 1. Introduction and Overview 2. Basic Principles of Fiber Composite Materials 3. Fibers for Polymer-Matrix Composites 4. Polymeric Matrix Materials 5. Component Form and Manufacture 6. Structural Analysis 7. Mechanical Property Measurement Contributors A. A. Baker* A. A. Baker A. Rachinger* A. A. Baker K. H. Leong* A. A. Baker J. Hodgkin ¢ M. Hou* A. A. Baker R. Paton* T. Kruckenburg* P. Falzon* I. Crouch* S. Dutton* M. Hou* X. Liu* W. Hillier* B. Hoskin* D. Kelly ~ R. Li § M. Bannister* A. A. Baker A. Garg ¶ A. A. Kharibi** Y. W. Mai** Affiliations at the time of drafting: *DSTO, Dept of Defence, Commonwealth of Australia *CRC-ACS Ltd. *Department of Molecular Science, CSIRO ~University of New South Wales ~Hawker De Havilland Aerospace Ltd. **University of Sydney

XX CONTRIBUTORS 8.Properties of Composite Systems A.A.Baker A.Mouritz R.Chester* M.Bannister 9.Joining of Composite Structures A.A.Baker D.Kelly 10.Repair Technology A.A.Baker 11.Quality Assurance A.A.Baker A.Crosky R.Vodicka* C.Howe 12.Aircraft Applications and Design Issues S.Dutton A.A.Baker 13.Airworthiness Considerations For B.C.Hoskin Airframe Structures A.A.Baker S.Dutton D.Bond P.Callus* 14.Three-Dimensionally Reinforced Preforms A.A.Baker and Composites K.H.Leong M.Bannister 15.Smart Structures A.A.Baker S.Galea* 16.Knowledge-Based Engineering, D.Kelly Computer-Aided Design,and Finite K.Wangs Element Analysis Affiliations at the time of drafting: DSTO,Dept of Defence,Commonwealth of Australia CRC-ACS Ltd. Department of Molecular Science,CSIRO SUniversity of New South Wales "Hawker De Havilland Acrospace Ltd. .University of Sydney Royal Melbourne Institute of Technology #Royal Australian Air Force

xx CONTRIBUTORS 8. Properties of Composite Systems 9. Joining of Composite Structures 10. Repair Technology 11. Quality Assurance 12. Aircraft Applications and Design Issues 13. Airworthiness Considerations For Airframe Structures 14. Three-Dimensionally Reinforced Preforms and Composites 15. Smart Structures 16. Knowledge-Based Engineering, Computer-Aided Design, and Finite Element Analysis A. A. Baker A. Mouritzt* R. Chester* M. Bannister A. A. Baker D. Kelly A. A. Baker A. A. Baker A. Crosky ~ R. Vodicka* C. Howe ¶ S. Dutton A. A. Baker B. C. Hoskin A. A. Baker S. Dutton D. Bond** P. Callus* A. A. Baker K. H. Leong M. Bannister A. A. Baker S. Galea* D. Kelly K. Wang § Affiliations at the time of drafting: *DSTO, Dept of Defence, Commonwealth of Australia *CRC-ACS Ltd. *Department of Molecular Science, CSIRO §University of New South Wales '~Hawker De Havilland Aerospace Ltd. **University of Sydney ttRoyal Melbourne Institute of Technology **Royal Australian Air Force

Contents Contributors xix Chapter 1 Introduction and Overview 1 1.1 General 1 1.2 Drivers for Improved Airframe Materials 3 1.3 High-Performance Fiber Composite Concepts 3 1.4 Fiber Reinforcements 6 1.5 Matrices 7 1.6 Polymer Matrix Composites 13 1.7 Non-polymeric Composite Systems 13 1.8 Hybrid Metal/PMC Composites References 21 Bibliography 2 Chapter 2 Basic Principles of Fiber Composite Materials 2.1 Introduction to Fiber Composite Systems 23 2.2 Micromechanical Versus Macromechanical View of Composites 2.3 Micromechanics 2.4 Elastic Constants 26 2.5 Micromechanics Approach to Strength 2.6 Simple Estimate of Compressive Strength 6 2.7 Off-axis Strength in Tension 45 2.8 Fracture Toughness of Unidirectional Composites References Chapter 3 Fibers for Polymer-Matrix Composites 3.1 Overview 3.2 Glass Fibers 3.3 Carbon Fibers 3.4 Boron Fibers 3.5 Silicon Carbide 3.6 Aramid Fibers 3.7 Orientated Polyethylene Fibers 557676913429 3.8 Dry Fiber Forms References

Contents Contributors Chapter 1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 Introduction and Overview General Drivers for Improved Airframe Materials High-Performance Fiber Composite Concepts Fiber Reinforcements Matrices Polymer Matrix Composites Non-polymeric Composite Systems Hybrid Metal/PMC Composites References Bibliography Chapter 2 2.1 2.2 Basic Principles of Fiber Composite Materials Introduction to Fiber Composite Systems Micromechanical Versus Macromechanical View of Composites 2.3 Micromechanics 2.4 Elastic Constants 2.5 Micromechanics Approach to Strength 2.6 Simple Estimate of Compressive Strength 2.7 Off-axis Strength in Tension 2.8 Fracture Toughness of Unidirectional Composites References Chapter 3 Fibers for Polymer-Matrix Composites 3.1 Overview 3.2 Glass Fibers 3.3 Carbon Fibers 3.4 Boron Fibers 3.5 Silicon Carbide 3.6 Aramid Fibers 3.7 Orientated Polyethylene Fibers 3.8 Dry Fiber Forms References xix 1 1 3 3 6 7 13 13 19 21 21 23 23 23 25 26 36 42 45 47 53 55 55 57 63 67 69 71 73 74 79

xiv CONTENTS Chapter 4 Polymeric Matrix Materials 81 4.1 Introduction 81 4.2 Thermoset and Thermoplastic Polymer Matrix Materials 86 4.3 Thermosetting Resin Systems 88 4.4 Thermoplastic Systems 108 References 112 Chapter 5 Component Form and Manufacture 113 5.1 Introduction 113 5.2 Outline of General Laminating Procedures 115 5.3 Laminating Procedures For Aircraft-Grade Composite Components 117 5.4 Liquid Resin Molding Techniques 132 5.5 Filament Winding 140 5.6 Pultrusion 145 5.7 Process Modelling 149 5.8 Tooling 158 5.9 Special Thermoplastic Techniques 162 References 169 Chapter 6 Structural Analysis 171 6.1 Overview 171 6.2 Laminate Theory 172 6.3 Stress Concentration and Edge Effects 191 6.4 Failure Theories 194 6.5 Fracture Mechanics 203 6.6 Failure Prediction Near Stress Raisers and Damage Tolerance 204 6.7 Buckling 207 6.8 Summary 209 References 209 Chapter 7 Mechanical Property Measurement 213 7.1 Introduction 213 7.2 Coupon Tests 216 7.3 Laboratory Simulation of Environmental Effects 225 7.4 Measurement of Residual Strength 7.5 Measurement of Interlaminar Fracture Energy References Chapter 8 Properties of Composite Systems 239 8.1 Introduction 239 8.2 Glass-Fiber Composite Systems 241 8.3 Boron Fiber Composite Systems 247 8.4 Aramid Fiber Composite Systems 249 8.5 Carbon Fiber Systems 251 8.6 Properties of Laminates 262

xiv CONTENTS Chapter 4 Polymeric Matrix Materials 4.1 Introduction 4.2 Thermoset and Thermoplastic Polymer Matrix Materials 4.3 Thermosetting Resin Systems 4.4 Thermoplastic Systems References Chapter 5 Component Form and Manufacture 5.1 Introduction 5.2 Outline of General Laminating Procedures 5.3 Laminating Procedures For Aircraft-Grade Composite Components 5.4 Liquid Resin Molding Techniques 5.5 Filament Winding 5.6 Pultrusion 5.7 Process Modelling 5.8 Tooling 5.9 Special Thermoplastic Techniques References Chapter 6 Structural Analysis 6.1 Overview 6.2 Laminate Theory 6.3 Stress Concentration and Edge Effects 6.4 Failure Theories 6.5 Fracture Mechanics 6.6 Failure Prediction Near Stress Raisers and Damage Tolerance 6.7 Buckling 6.8 Summary References Chapter 7 Mechanical Property Measurement 7.1 Introduction 7.2 Coupon Tests 7.3 Laboratory Simulation of Environmental Effects 7.4 Measurement of Residual Strength 7.5 Measurement of Interlaminar Fracture Energy References Chapter 8 Properties of Composite Systems 8.1 Introduction 8.2 Glass-Fiber Composite Systems 8.3 Boron Fiber Composite Systems 8.4 Aramid Fiber Composite Systems 8.5 Carbon Fiber Systems 8.6 Properties of Laminates 81 81 86 88 108 112 113 113 115 117 132 140 145 149 158 162 169 171 171 172 191 194 203 204 207 209 209 213 213 216 225 227 231 237 239 239 241 247 249 257 262

CONTENTS V 8.7 Impact Damage Resistance 263 8.8 Fatigue of Composite Laminates 266 8.9 Environmental Effects 276 References 286 Chapter 9 Joining of Composite Structures 289 9.1 Introduction 289 9.2 Comparison Between Mechanically Fastened and Adhesively Bonded Joints 290 9.3 Adhesively Bonded Joints 292 9.4 Mechanically Fastened Joints 337 References 366 Chapter 10 Repair Technology 369 10.1 Introduction 369 10.2 Assessment of the Need to Repair 369 10.3 Classification of Types of Structure 371 10.4 Repair Requirements 371 10.5 Non-patch Repairs 374 10.6 Patch Repairs:General Considerations 377 10.7 Bonded Patch Repairs 379 10.8 Materials Engineering Aspects 390 10.9 Application Technology:In Situ Repairs 394 10.10 Bolted Repairs 395 10.11 Materials Engineering Aspects 398 References 401 Chapter 11 Quality Assurance 403 11.1 Introduction 403 11.2 Quality Control 403 11.3 Cure Monitoring 408 11.4 Non-destructive Inspection of Advanced Composite Aerospace Structures 414 11.5 Conclusion 430 References 431 Chapter 12 Aircraft Applications and Design Issues 435 12.1 Overview 435 12.2 Applications of Glass-Fiber Composites 435 12.3 Current Applications 436 12.4 Design Considerations 447 12.5 Design of Carbon-Fiber-Based Components 449 12.6 Design Methodologies 462

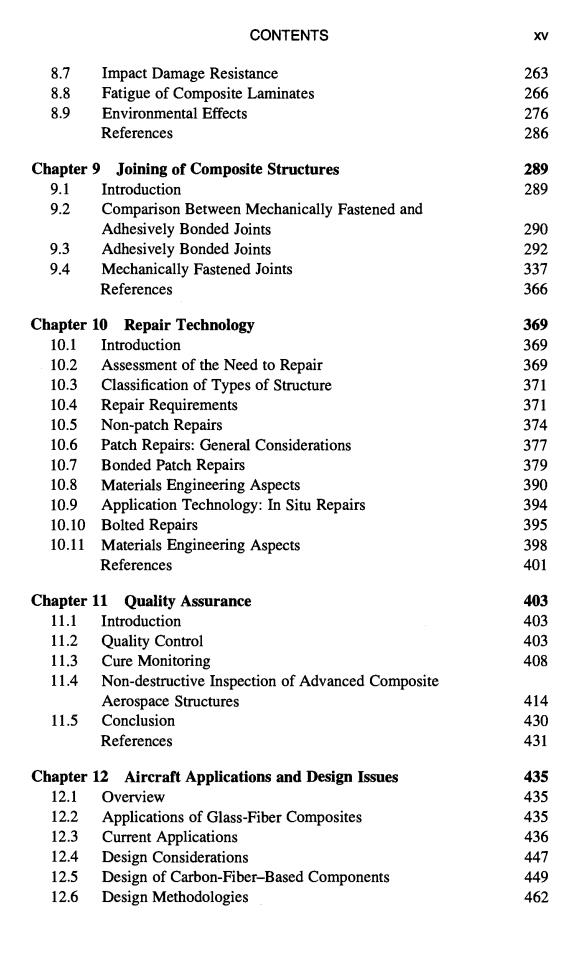

CONTENTS xv 8.7 8.8 8.9 Impact Damage Resistance Fatigue of Composite Laminates Environmental Effects References 263 266 276 286 Chapter 9 9.1 9.2 9.3 9.4 Joining of Composite Structures Introduction Comparison Between Mechanically Fastened and Adhesively Bonded Joints Adhesively Bonded Joints Mechanically Fastened Joints References 289 289 290 292 337 366 Chapter 10 10.1 10.2 10.3 10.4 10.5 10.6 10.7 10.8 10.9 10.10 10.11 Repair Technology Introduction Assessment of the Need to Repair Classification of Types of Structure Repair Requirements Non-patch Repairs Patch Repairs: General Considerations Bonded Patch Repairs Materials Engineering Aspects Application Technology: In Situ Repairs Bolted Repairs Materials Engineering Aspects References 369 369 369 371 371 374 377 379 390 394 395 398 401 Chapter 11 Quality Assurance 11.1 Introduction 11.2 Quality Control 11.3 Cure Monitoring 11.4 Non-destructive Inspection of Advanced Composite Aerospace Structures 11.5 Conclusion References 403 403 403 408 414 430 431 Chapter 12 12.1 12.2 12.3 12.4 12.5 12.6 Aircraft Applications and Design Issues Overview Applications of Glass-Fiber Composites Current Applications Design Considerations Design of Carbon-Fiber-Based Components Design Methodologies 435 435 435 436 447 449 462