Liquid Filling 1. Introduction ⚫ Liquid products: alcohol and soda water ⚫ Semi-liquid products: toothpaste, peanut butter, and caulking compound

Liquid Filling 1. Introduction ⚫ Liquid products: alcohol and soda water ⚫ Semi-liquid products: toothpaste, peanut butter, and caulking compound

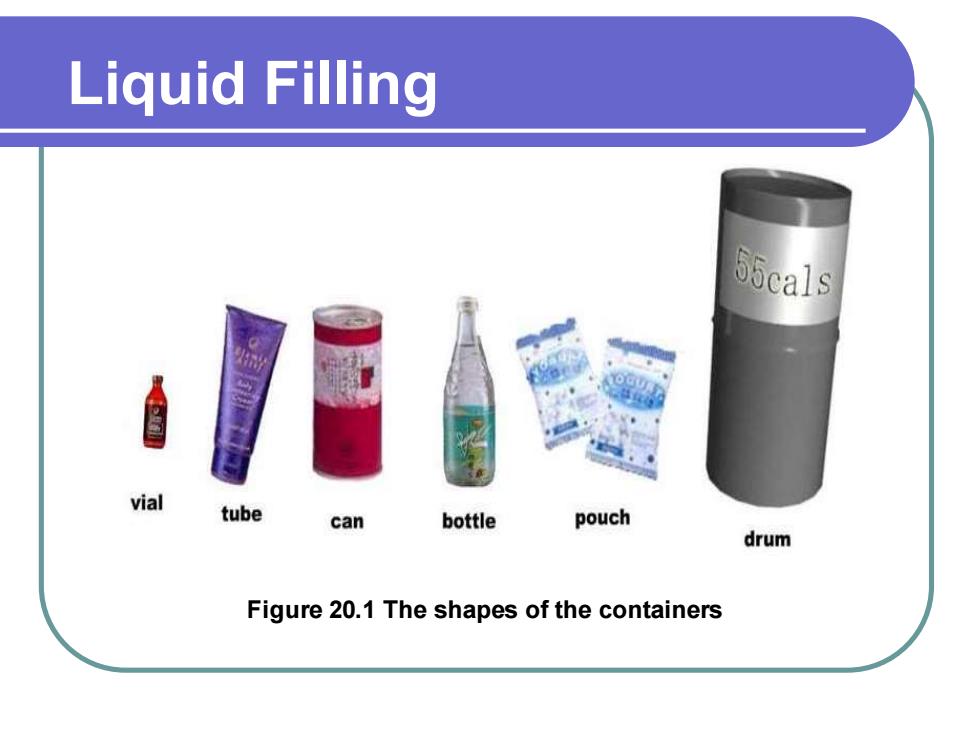

Liquid Filling 2. Types of Filling Machines ⚫ The containers may be made of plastic, metal, glass, treated paperboard, or a number of other materials. ⚫ The shapes of the containers include those of bottles, jars, vials, tubes, cans, pouches, cartons, and drums (Figure 20.1)

Liquid Filling 2. Types of Filling Machines ⚫ The containers may be made of plastic, metal, glass, treated paperboard, or a number of other materials. ⚫ The shapes of the containers include those of bottles, jars, vials, tubes, cans, pouches, cartons, and drums (Figure 20.1)

Figure 20.1 The shapes of the containers Liquid Filling

Figure 20.1 The shapes of the containers Liquid Filling

⚫ Most liquid and semi-liquid products are filled by one of two major methods: volumetric, or constant level filling. ⚫ In volumetric filling the amount of product is premeasured so that each container has the same volume of product. ⚫ Constant level filling techniques fill each container to the same level, so it is frequently called the “fill-to-a-level” method. Liquid Filling

⚫ Most liquid and semi-liquid products are filled by one of two major methods: volumetric, or constant level filling. ⚫ In volumetric filling the amount of product is premeasured so that each container has the same volume of product. ⚫ Constant level filling techniques fill each container to the same level, so it is frequently called the “fill-to-a-level” method. Liquid Filling

Liquid Filling 3. Use of Filling Machines ⚫ Volumetric filling is particularly appropriate for applications in the pharmaceutical industry where it is important that each container is accurately filled with a specific volume of product. ⚫ Constant level filling is used with see-through bottles in which it is important that all of the bottles in a display appear to be filled to the same level, although the bottles may not be exactly the same size and the volumes may be slightly different

Liquid Filling 3. Use of Filling Machines ⚫ Volumetric filling is particularly appropriate for applications in the pharmaceutical industry where it is important that each container is accurately filled with a specific volume of product. ⚫ Constant level filling is used with see-through bottles in which it is important that all of the bottles in a display appear to be filled to the same level, although the bottles may not be exactly the same size and the volumes may be slightly different