10 LANDFILL MANUALS 4.SITE INFASTRUCTURE 4.1 INTRODUCTION Haul roads from the reception area to the entrance to each phase should be designed to a standard Site principal infrastructure elements are listed adequate to allow trafficking of heavy vehicles.Haul below and discussed in greater detail in the sections roads may need to accommodate the passage of that follow.They are: heavy construction vehicles e.g.steel wheel compactors and tracked bulldozers. access and traffic control: Service roads to other facilities on site e.g.leachate site accommodation and compounds: treatment plant,gas extraction system,should be to an adequate standard to allow access by service ·weighbridges, vehicles. wheel cleaners; Typical details for the access road,service road and haul roads are given in Figure 4.1.The materials ·site services, required for road construction should be included in the materials balance requirements.The use of civic waste facilities:and construction/demolition waste as a roadbase material should be considered.The use of geosynthetic ·security. reinforcement,eg geotextiles,may be required on weak or waste subgrades 4.2 ACCESS AND TRAFFIC CONTROL Particular attention should be given to the access In designing a landfill site consideration should have point to each cell.It is important that the access been given to access at the planning stage.Access routes chosen do not put the liner at risk.Typical can be by road,rail or water but in Ireland is access ramps will be up to 6m in width and have typically by road. slopes up to 10%.A schematic of a typical access ramp is shown in Figure 4.2. In cases where access to the landfill site is to be by road then the impact of the proposed development on Traffic signs within the landfill site should include the existing road network should be examined.The stop signs and directional signs to reception, results of a traffic analysis will determine if specific weighbridge,carpark and civic waste area etc.The provisions are required to deal with the anticipated designer is referred to DoE,'Traffic Signs Manual. traffic flow.The existing road network may need 1996'for further guidance on signs.In addition to upgrading to deal with the increase in traffic to the traffic signs provision should be made for the site or a dedicated road linking the nearest inclusion of a site sign at the site entrance.This primary/secondary route to the proposed site may be should specify relevant details,opening hours,types required.In any case an analysis prior to detailed of waste accepted,site licence number,contact design should ensure that the potential for damaging numbers,etc. existing road surfaces and the queuing of traffic on the public road are addressed. The access road including the reception area should be paved to highway standard and should have a minimum width of 6m.Consideration should be given to the provision of passing points.Road design should be carried out in accordance with the National Roads Authority (NRA)'Manual of Contract Documents for Roadworks'-of which Volume 1 is the Specification for Roadworks

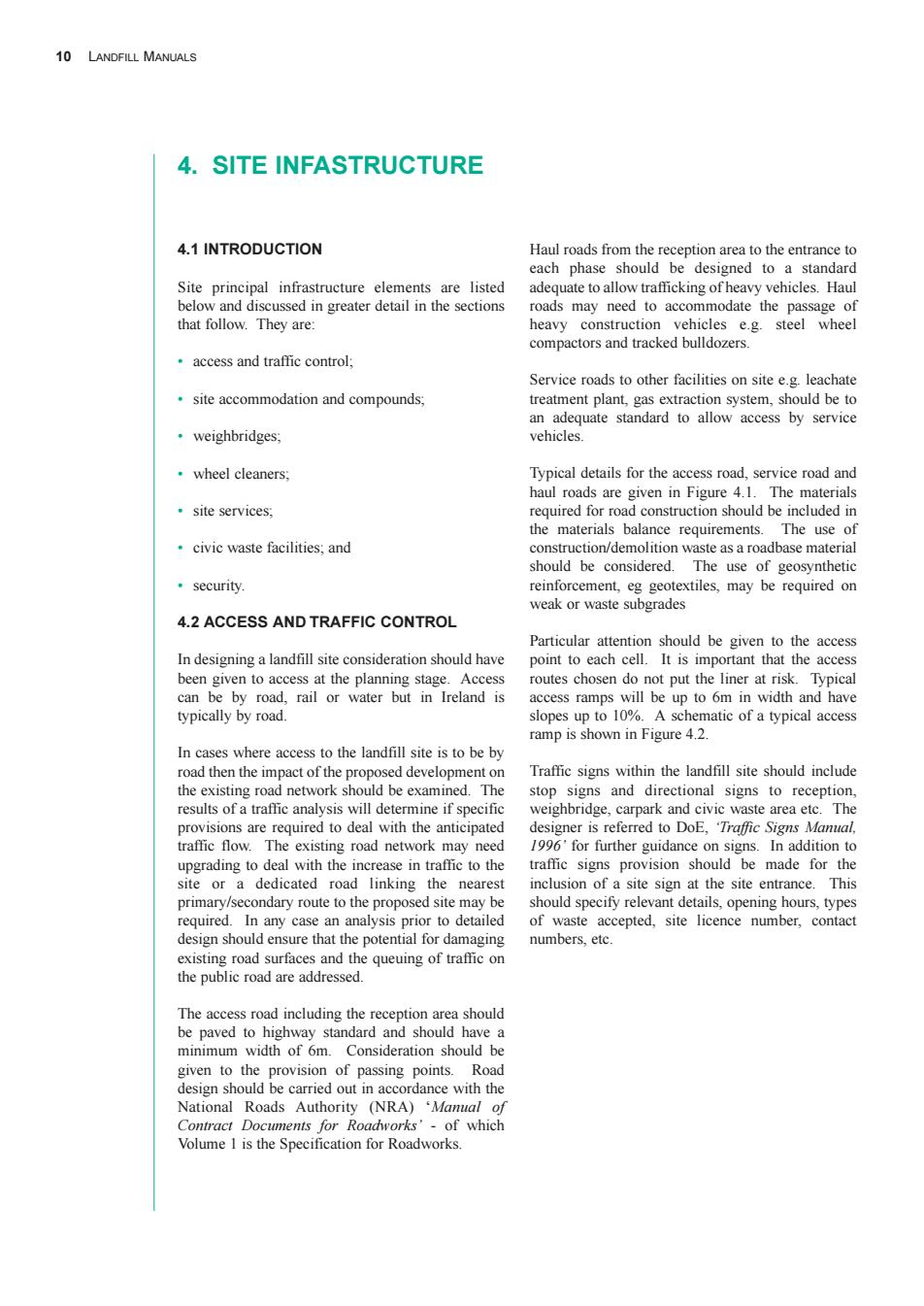

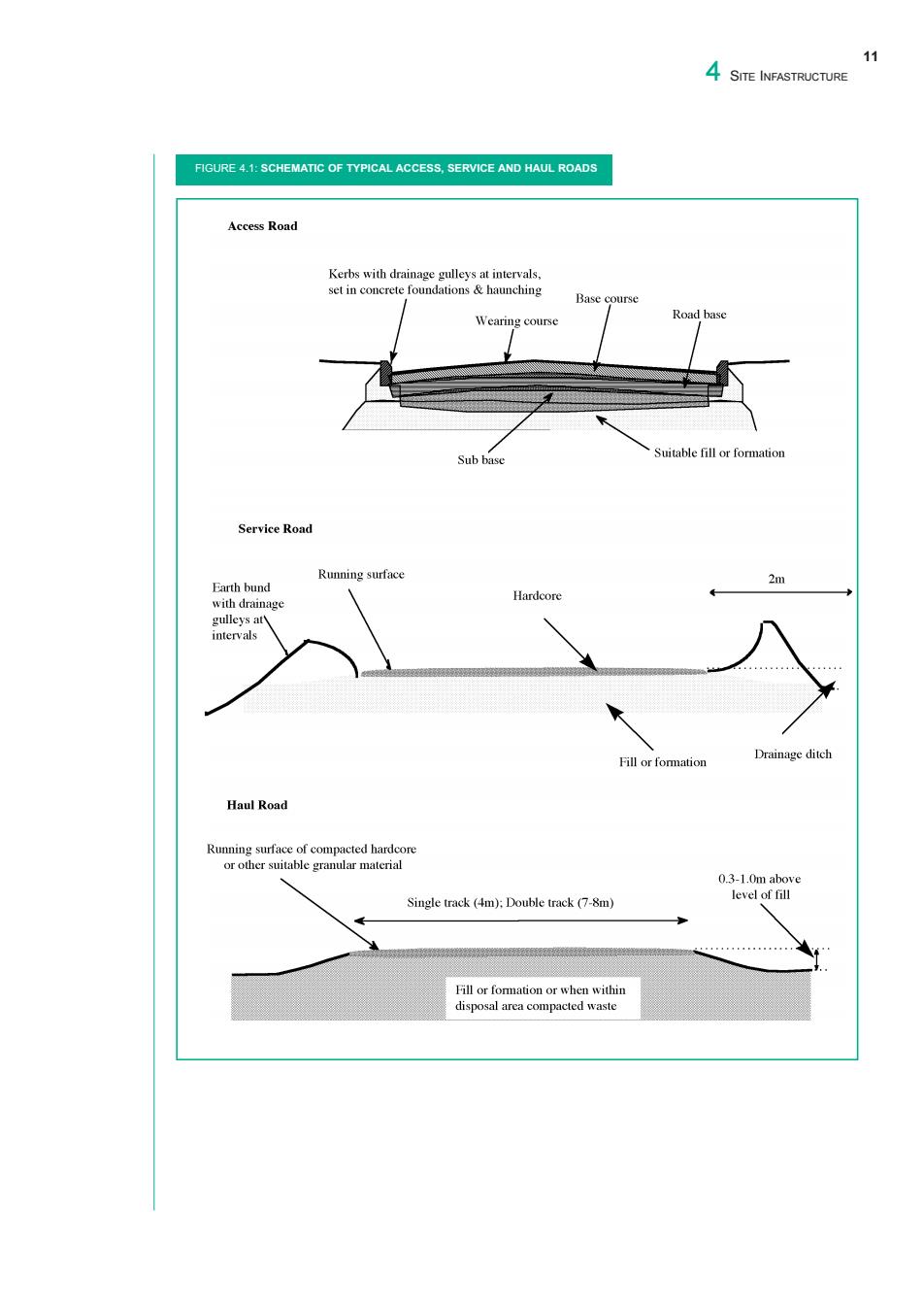

4.1 INTRODUCTION Site principal infrastructure elements are listed below and discussed in greater detail in the sections that follow. They are: • access and traffic control; • site accommodation and compounds; • weighbridges; • wheel cleaners; • site services; • civic waste facilities; and • security. 4.2 ACCESS AND TRAFFIC CONTROL In designing a landfill site consideration should have been given to access at the planning stage. Access can be by road, rail or water but in Ireland is typically by road. In cases where access to the landfill site is to be by road then the impact of the proposed development on the existing road network should be examined. The results of a traffic analysis will determine if specific provisions are required to deal with the anticipated traffic flow. The existing road network may need upgrading to deal with the increase in traffic to the site or a dedicated road linking the nearest primary/secondary route to the proposed site may be required. In any case an analysis prior to detailed design should ensure that the potential for damaging existing road surfaces and the queuing of traffic on the public road are addressed. The access road including the reception area should be paved to highway standard and should have a minimum width of 6m. Consideration should be given to the provision of passing points. Road design should be carried out in accordance with the National Roads Authority (NRA) ‘Manual of Contract Documents for Roadworks’ - of which Volume 1 is the Specification for Roadworks. Haul roads from the reception area to the entrance to each phase should be designed to a standard adequate to allow trafficking of heavy vehicles. Haul roads may need to accommodate the passage of heavy construction vehicles e.g. steel wheel compactors and tracked bulldozers. Service roads to other facilities on site e.g. leachate treatment plant, gas extraction system, should be to an adequate standard to allow access by service vehicles. Typical details for the access road, service road and haul roads are given in Figure 4.1. The materials required for road construction should be included in the materials balance requirements. The use of construction/demolition waste as a roadbase material should be considered. The use of geosynthetic reinforcement, eg geotextiles, may be required on weak or waste subgrades Particular attention should be given to the access point to each cell. It is important that the access routes chosen do not put the liner at risk. Typical access ramps will be up to 6m in width and have slopes up to 10%. A schematic of a typical access ramp is shown in Figure 4.2. Traffic signs within the landfill site should include stop signs and directional signs to reception, weighbridge, carpark and civic waste area etc. The designer is referred to DoE, ‘Traffic Signs Manual, 1996’ for further guidance on signs. In addition to traffic signs provision should be made for the inclusion of a site sign at the site entrance. This should specify relevant details, opening hours, types of waste accepted, site licence number, contact numbers, etc. 4. SITE INFASTRUCTURE 10 LANDFILL MANUALS

11 4SITE INFASTRUCTURE FIGURE 4.1:SCHEMATIC OF TYPICAL ACCESS,SERVICE AND HAUL ROADS Access Road Kerbs with drainage gulleys at intervals, set in concrete foundations haunching Base course Wearing course Road base Sub base Suitable fill or formation Service Road Running surface 2m Earth bund with drainage Hardcore gulleys at intervals Fill or formation Drainage ditch Haul Road Running surface of compacted hardcore or other suitable granular material 0.3-1.0m above Single track (4m):Double track (7-8m) level of fill Fill or formation or when within disposal area compacted waste

FIGURE 4.1: SCHEMATIC OF TYPICAL ACCESS, SERVICE AND HAUL ROADS 11 4 SITE INFASTRUCTURE

12 LANDFILL MANUALS FIGURE 4.2:TYPICAL ACCESS RAMP Geometry of a Typical Access Ramp to a cell Cross-Section of Ramp Roadway Roadway(ypically6m) 一Edge bund Sub-base Geotextile or Sacrificial Geomembrane Leachate Collection Layer -Flexible Membrane 》 Liner Composite Compacted Mineral Liner Layer

FIGURE 4.2: TYPICAL ACCESS RAMP 12 LANDFILL MANUALS

13 4 SITE INFASTRUCTURE 4.3 SITE ACCOMMODATION adjacent to the administration building with easy access to reception and should not be accessible to Site accommodation must be designed,constructed traffic hauling waste to the landfill site. and maintained to a high standard. 4.4 WEIGHBRIDGES Site accommodation should include the following facilities: A weighbridge is required for the accurate weighing of incoming waste.The weighbridge should be administration building consisting of an located adjacent to the waste reception area and administration office,first aid area and genera sufficiently far enough away from the public road to reception area; avoid queuing onto the road.Weighing facilities should be adequate to accommodate the weighing of sanitary facilities:showers and toilets; both incoming and outgoing traffic if necessary. staff facilities:lockers and mess room; There are three general types of weighbridges; pitmounted,surface mounted and axle weighers. waste reception area; The advantages and disadvantages of each type are presented in Table 4.1.When selecting a monitoring equipment store; weighbridge consideration will have to be given to: equipment maintenance and fuel storage;and required length;and 。parking area. 。load capacity. It is recommended that purpose built buildings be It is recommended the length of the weighbridge constructed.On-site laboratory facilities should be should be,at minimum,15m with a minimum load provided where necessary.The administration bearing capacity of 60 tonnes.The cost of building should include a working telephone,a maintenance/calibration of a weighbridge may be facsimile machine and should be suitable for the significant. storage of records. It is normal practice for companies which provide The waste reception area is an important part of the weighbridges to supply and install the unit.The infrastructure of a landfill facility as it is used to weighbridge is normally installed to a standard determine whether a waste should be accepted for specification supplied by the weighbridge disposal to the site or not.The waste inspection manufacturer. Foundations to receive the facility should be located so as to cause minimum weighbridge must be constructed to the details disturbance to other traffic using the landfill facility. supplied by the manufacturer and designer. It should be constructed on an impervious hardstanding area with retaining bunds.Drainage Suppliers of the weighbridge unit will also normally from this area should be independent of the rest of provide computerised software for recording details the reception area and should be discharged to the of the incoming waste.When selecting the foul sewer or leachate treatment plant computerised software,consideration should be given to the information to be provided to the On site compounds are required for equipment Agency under the requirements of the waste licence. maintenance and fuel storage.Fuel and oil should be stored in clearly marked and controlled areas.Tanks or containers for fuel and oil should be surrounded by a secure bund which is able to contain at least 110%of the capacity of the largest tank.Guidance on the construction and testing of bunds is given in Appendix A.The location and specification of fuel/oil tanks should be agreed with the County Fire Officer. The parking area should provide sufficient parking spaces for staff and visitors.It should be located

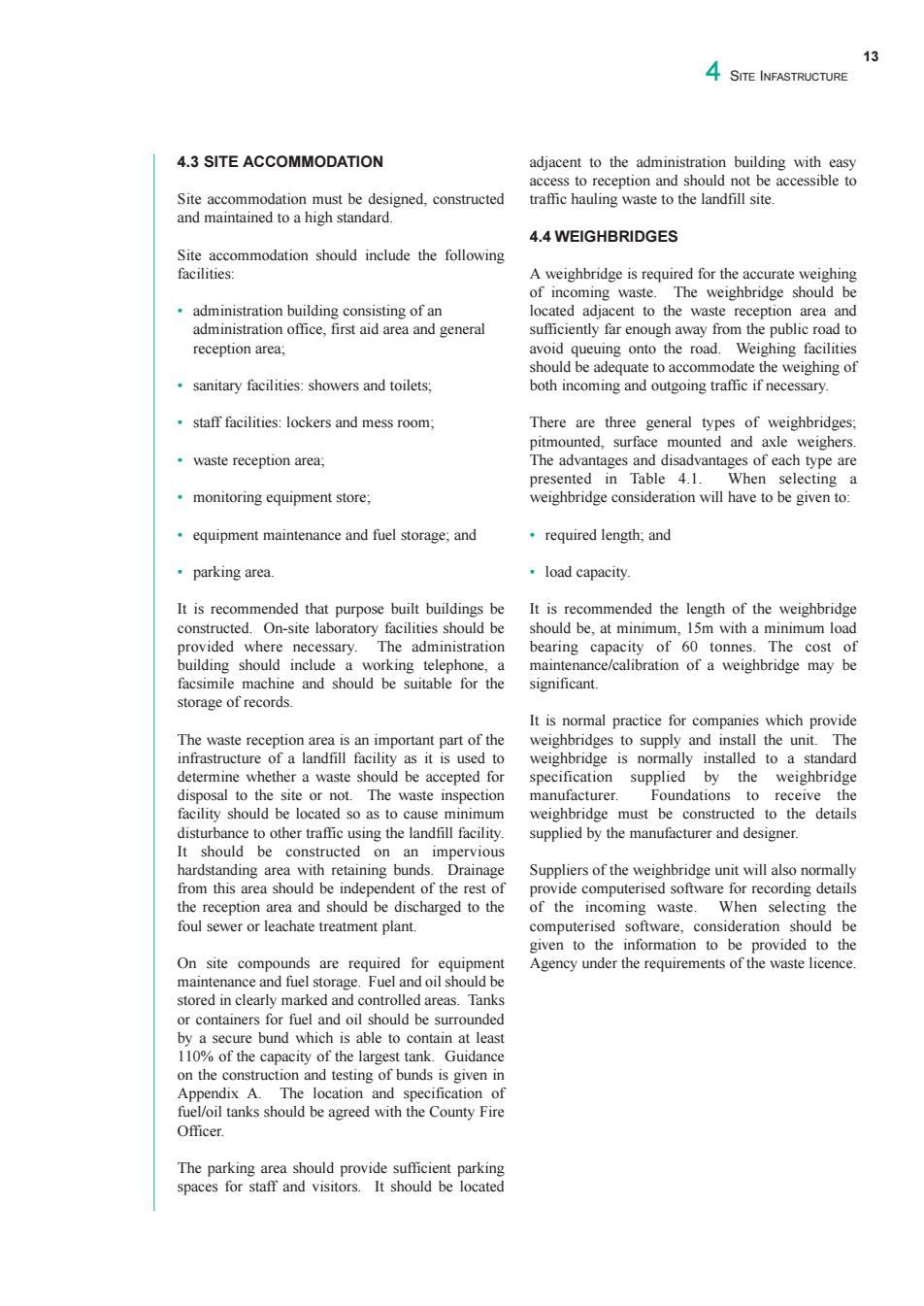

4.3 SITE ACCOMMODATION Site accommodation must be designed, constructed and maintained to a high standard. Site accommodation should include the following facilities: • administration building consisting of an administration office, first aid area and general reception area; • sanitary facilities: showers and toilets; • staff facilities: lockers and mess room; • waste reception area; • monitoring equipment store; • equipment maintenance and fuel storage; and • parking area. It is recommended that purpose built buildings be constructed. On-site laboratory facilities should be provided where necessary. The administration building should include a working telephone, a facsimile machine and should be suitable for the storage of records. The waste reception area is an important part of the infrastructure of a landfill facility as it is used to determine whether a waste should be accepted for disposal to the site or not. The waste inspection facility should be located so as to cause minimum disturbance to other traffic using the landfill facility. It should be constructed on an impervious hardstanding area with retaining bunds. Drainage from this area should be independent of the rest of the reception area and should be discharged to the foul sewer or leachate treatment plant. On site compounds are required for equipment maintenance and fuel storage. Fuel and oil should be stored in clearly marked and controlled areas. Tanks or containers for fuel and oil should be surrounded by a secure bund which is able to contain at least 110% of the capacity of the largest tank. Guidance on the construction and testing of bunds is given in Appendix A. The location and specification of fuel/oil tanks should be agreed with the County Fire Officer. The parking area should provide sufficient parking spaces for staff and visitors. It should be located adjacent to the administration building with easy access to reception and should not be accessible to traffic hauling waste to the landfill site. 4.4 WEIGHBRIDGES A weighbridge is required for the accurate weighing of incoming waste. The weighbridge should be located adjacent to the waste reception area and sufficiently far enough away from the public road to avoid queuing onto the road. Weighing facilities should be adequate to accommodate the weighing of both incoming and outgoing traffic if necessary. There are three general types of weighbridges; pitmounted, surface mounted and axle weighers. The advantages and disadvantages of each type are presented in Table 4.1. When selecting a weighbridge consideration will have to be given to: • required length; and • load capacity. It is recommended the length of the weighbridge should be, at minimum, 15m with a minimum load bearing capacity of 60 tonnes. The cost of maintenance/calibration of a weighbridge may be significant. It is normal practice for companies which provide weighbridges to supply and install the unit. The weighbridge is normally installed to a standard specification supplied by the weighbridge manufacturer. Foundations to receive the weighbridge must be constructed to the details supplied by the manufacturer and designer. Suppliers of the weighbridge unit will also normally provide computerised software for recording details of the incoming waste. When selecting the computerised software, consideration should be given to the information to be provided to the Agency under the requirements of the waste licence. 13 4 SITE INFASTRUCTURE

14 LANDFILL MANUALS TABLE 4.1:WEIGHBRIDGE TYPES:-ADVANTAGES/DISADVANTAGES Weighbridge type Advantage Disadvantage Pit mounted No ramps required Difficult to relocate Access required under weighbridge for maintenance Surface mounted Easy to install Ramps required May be relocated Reduced amount of engineering work required Axle weighers Low cost Not very accurate 4.5 WHEEL CLEANER ·fire water, A wheel cleaner is essential at a landfill site to wastewater(removal/treatment);and prevent mud from being carried out onto the public road.There are various types of wheel cleaning units ·power supply available (Figure 4.3).In general a shaker bar arrangement without the use of water or an Lighting should be provided in areas in operation arrangement with water or a combination of both is after darkness.This should include the access from used.In addition to a wheel/chassis wash, the public road to the site reception area and site consideration should be given to the provision of a facilities which may require maintenance outside full truck wash.At a minimum this would include a normal working hours e.g.weighbridge,wheel lance/steam cleaner cleaner,civic waste area etc. Consideration should be given to employing a one A water supply is required for general on-site way system through the wheel cleaner.The design everyday purposes.In addition,there should be of the wheel cleaning unit should ensure that there is sufficient water storage for fire fighting.The chief a stable foundation below the unit and that the fire officer of the relevant local authority should be structure of the unit is capable of taking the weight consulted in relation to fire control at the facility. of the trucks 4.7 CIVIC WASTE FACILITIES Where water is to be used as part of the wheel cleaner facility a water supply,drainage area and an The principal function of a civic waste facility is to area of hardstanding is required.Contaminated provide householders and commercial operators with water should be discharged to an appropriate a convenient centre to drop off recyclables and other treatment system,eg foul sewer,leachate treatment wastes.It normally consists of a variety of plant,etc containers designated for specific wastes and dedicated areas to allow for collection of wastes such 4.6 SITE SERVICES as green waste.construction/demolition waste and bulky items.There is a growing tendency to develop The design should include provision for the civic waste sites as stand alone facilities but these following services: facilities are also commonly incorporated as part of the infrastructure of a landfill. ·lighting, A civic waste facility located on a landfill site should 。telephone/fax be accessible and capable of handling large traffic flows.The entrance and drive-in area should be telemetry -continuous monitoring (CCTV)where paved.All collection containers should be placed on required; a paved surface.If waste intake is expected to be high consideration should be given to a split level ·water supply, arrangement,with skips on the lower level.Where provisions are made for the collection of batteries

4.5 WHEEL CLEANER A wheel cleaner is essential at a landfill site to prevent mud from being carried out onto the public road. There are various types of wheel cleaning units available (Figure 4.3). In general a shaker bar arrangement without the use of water or an arrangement with water or a combination of both is used. In addition to a wheel/chassis wash, consideration should be given to the provision of a full truck wash. At a minimum this would include a lance/steam cleaner. Consideration should be given to employing a one way system through the wheel cleaner. The design of the wheel cleaning unit should ensure that there is a stable foundation below the unit and that the structure of the unit is capable of taking the weight of the trucks. Where water is to be used as part of the wheel cleaner facility a water supply, drainage area and an area of hardstanding is required. Contaminated water should be discharged to an appropriate treatment system, eg foul sewer, leachate treatment plant, etc. 4.6 SITE SERVICES The design should include provision for the following services: • lighting; • telephone/fax; • telemetry - continuous monitoring (CCTV) where required; • water supply; • fire water; • wastewater (removal/treatment); and • power supply. Lighting should be provided in areas in operation after darkness. This should include the access from the public road to the site reception area and site facilities which may require maintenance outside normal working hours e.g. weighbridge, wheel cleaner, civic waste area etc. A water supply is required for general on-site everyday purposes. In addition, there should be sufficient water storage for fire fighting. The chief fire officer of the relevant local authority should be consulted in relation to fire control at the facility. 4.7 CIVIC WASTE FACILITIES The principal function of a civic waste facility is to provide householders and commercial operators with a convenient centre to drop off recyclables and other wastes. It normally consists of a variety of containers designated for specific wastes and dedicated areas to allow for collection of wastes such as green waste, construction/demolition waste and bulky items. There is a growing tendency to develop civic waste sites as stand alone facilities but these facilities are also commonly incorporated as part of the infrastructure of a landfill. A civic waste facility located on a landfill site should be accessible and capable of handling large traffic flows. The entrance and drive-in area should be paved. All collection containers should be placed on a paved surface. If waste intake is expected to be high consideration should be given to a split level arrangement, with skips on the lower level. Where provisions are made for the collection of batteries, TABLE 4.1: WEIGHBRIDGE TYPES:- ADVANTAGES/DISADVANTAGES Weighbridge type Advantage Disadvantage Pit mounted No ramps required Difficult to relocate Access required under weighbridge for maintenance Surface mounted Easy to install Ramps required May be relocated Reduced amount of engineering work required Axle weighers Low cost Not very accurate 14 LANDFILL MANUALS