Step 1 Determine Product Fragility ⚫ Fragility is normally expressed in units of “g’s” and indicates the maximum deceleration the product can withstand without being damaged. The more fragile a product is, the lower its g-factor(Table 15.1)

Step 1 Determine Product Fragility ⚫ Fragility is normally expressed in units of “g’s” and indicates the maximum deceleration the product can withstand without being damaged. The more fragile a product is, the lower its g-factor(Table 15.1)

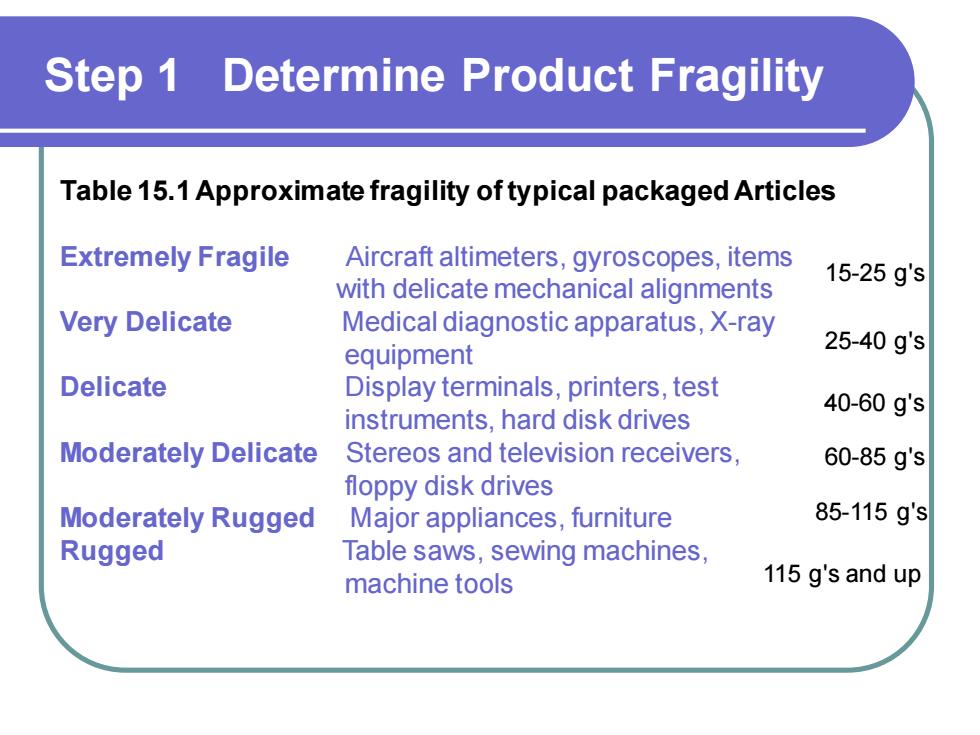

Step 1 Determine Product Fragility Table 15.1 Approximate fragility of typical packaged Articles Extremely Fragile Aircraft altimeters, gyroscopes, items with delicate mechanical alignments Very Delicate Medical diagnostic apparatus, X-ray equipment Delicate Display terminals, printers, test instruments, hard disk drives Moderately Delicate Stereos and television receivers, floppy disk drives Moderately Rugged Major appliances, furniture Rugged Table saws, sewing machines, machine tools 15-25 g's 25-40 g's 40-60 g's 85-115 g's 60-85 g's 115 g's and up

Step 1 Determine Product Fragility Table 15.1 Approximate fragility of typical packaged Articles Extremely Fragile Aircraft altimeters, gyroscopes, items with delicate mechanical alignments Very Delicate Medical diagnostic apparatus, X-ray equipment Delicate Display terminals, printers, test instruments, hard disk drives Moderately Delicate Stereos and television receivers, floppy disk drives Moderately Rugged Major appliances, furniture Rugged Table saws, sewing machines, machine tools 15-25 g's 25-40 g's 40-60 g's 85-115 g's 60-85 g's 115 g's and up

Step 1 Determine Product Fragility ⚫ The highest deceleration, which did not cause damage, is then known to be the product’s g-factor. ⚫ It may be necessary to determine fragility levels for a product in various orientations. ⚫ If the g-factor is estimated too high, and the product is unable to survive as much shock as anticipated, the packaging will be underdesigned and significant shipping damage is likely to occur. ⚫ If the g-factor is estimated too low, and the product can actually withstand more shock than anticipated, the packaging will be overdesigned and unnecessarily expensive

Step 1 Determine Product Fragility ⚫ The highest deceleration, which did not cause damage, is then known to be the product’s g-factor. ⚫ It may be necessary to determine fragility levels for a product in various orientations. ⚫ If the g-factor is estimated too high, and the product is unable to survive as much shock as anticipated, the packaging will be underdesigned and significant shipping damage is likely to occur. ⚫ If the g-factor is estimated too low, and the product can actually withstand more shock than anticipated, the packaging will be overdesigned and unnecessarily expensive

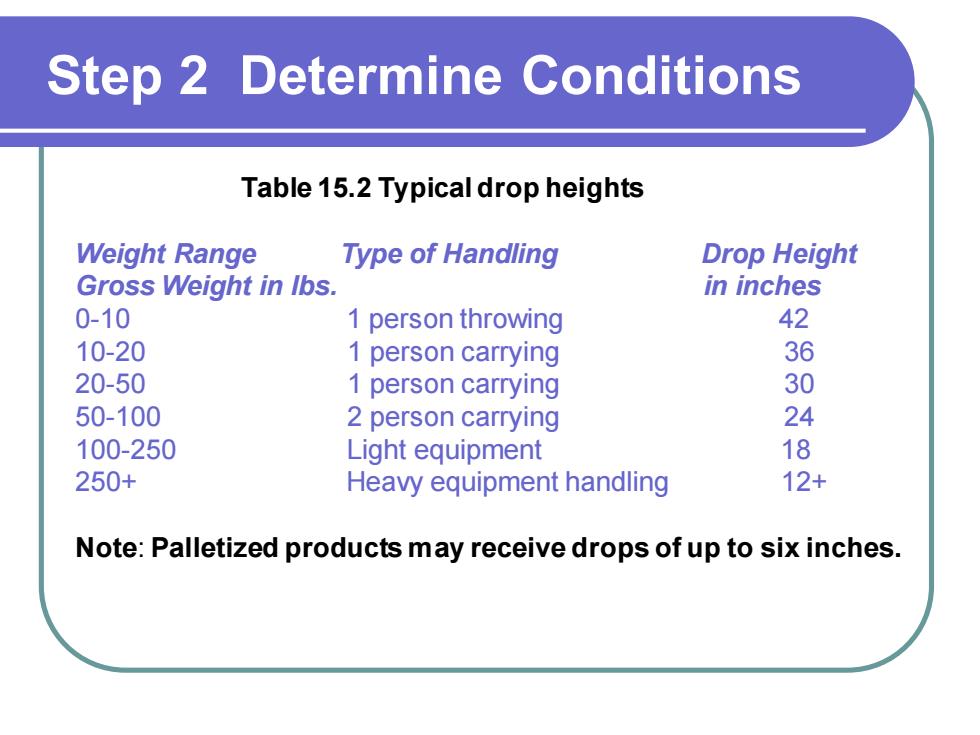

Step 2 Determine Conditions ⚫ Drop heights are generally established by the product's weight, which usually reflect how the product will be handled(Table 15.2)

Step 2 Determine Conditions ⚫ Drop heights are generally established by the product's weight, which usually reflect how the product will be handled(Table 15.2)

Step 2 Determine Conditions Table 15.2 Typical drop heights Weight Range Type of Handling Drop Height Gross Weight in lbs. in inches 0-10 1 person throwing 42 10-20 1 person carrying 36 20-50 1 person carrying 30 50-100 2 person carrying 24 100-250 Light equipment 18 250+ Heavy equipment handling 12+ Note: Palletized products may receive drops of up to six inches

Step 2 Determine Conditions Table 15.2 Typical drop heights Weight Range Type of Handling Drop Height Gross Weight in lbs. in inches 0-10 1 person throwing 42 10-20 1 person carrying 36 20-50 1 person carrying 30 50-100 2 person carrying 24 100-250 Light equipment 18 250+ Heavy equipment handling 12+ Note: Palletized products may receive drops of up to six inches