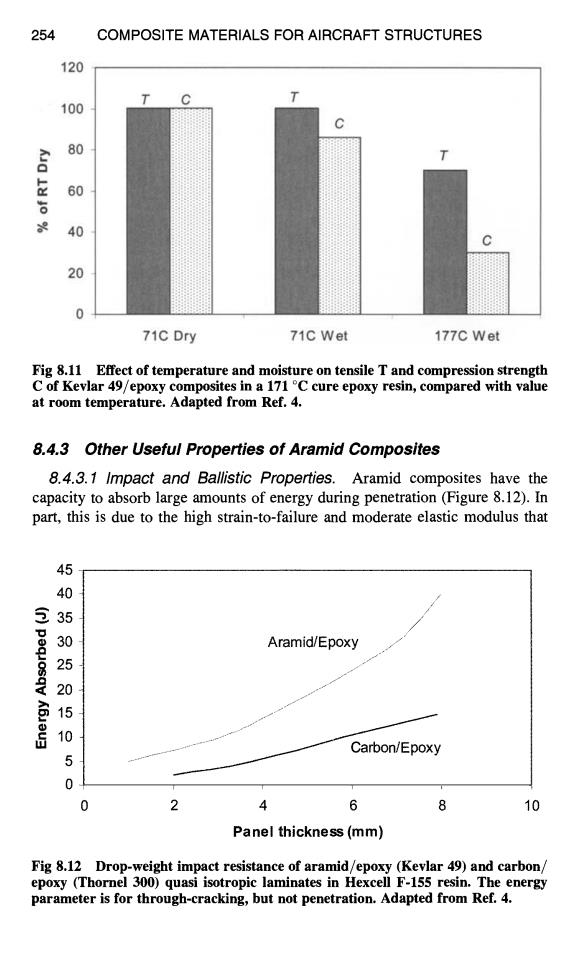

254 COMPOSITE MATERIALS FOR AIRCRAFT STRUCTURES 120 100 80 60 40 20 71C Dry 71C Wet 177C Wet Fig 8.11 Effect of temperature and moisture on tensile T and compression strength C of Kevlar 49/epoxy composites in a 171C cure epoxy resin,compared with value at room temperature.Adapted from Ref.4. 8.4.3 Other Useful Properties of Aramid Composites 8.4.3.1 Impact and Ballistic Properties.Aramid composites have the capacity to absorb large amounts of energy during penetration (Figure 8.12).In part,this is due to the high strain-to-failure and moderate elastic modulus that 45 40 35 025 Aramid/Epoxy 0 15 10 Carbon/Epoxy 5 0 0 2 4 6 8 10 Panel thickness(mm) Fig 8.12 Drop-weight impact resistance of aramid/epoxy (Kevlar 49)and carbon/ epoxy (Thornel 300)quasi isotropic laminates in Hexcell F-155 resin.The energy parameter is for through-cracking,but not penetration.Adapted from Ref.4

254 COMPOSITE MATERIALS FOR AIRCRAFT STRUCTURES 120 I-- o 100 80 60 40 20 0 T C T 71C Dry 71C Wet 177C Wet Fig 8.11 Effect of temperature and moisture on tensile T and compression strength C of Kevlar 49/epoxy composites in a 171 °C cure epoxy resin, compared with value at room temperature. Adapted from Ref. 4. 8.4.3 Other Useful Properties of Aramid Composites 8.4.3.1 Impact and Ballistic Properties. Aramid composites have the capacity to absorb large amounts of energy during penetration (Figure 8.12). In part, this is due to the high strain-to-failure and moderate elastic modulus that 45 40 A ~ 35 "o 30 £ ~ 25 < 20 o " 10 w 5 / / / / Aramid/Epoxy .... " fs .- ....... "J/ "J" ~y 0 2 4 6 8 10 Panel thickness (mm) Fig 8.12 Drop-weight impact resistance of aramid/epoxy (Kevlar 49) and carbon/ epoxy (Thornel 300) quasi isotropic laminates in Hexcell F-155 resin. The energy parameter is for through-cracking, but not penetration. Adapted from Ref. 4

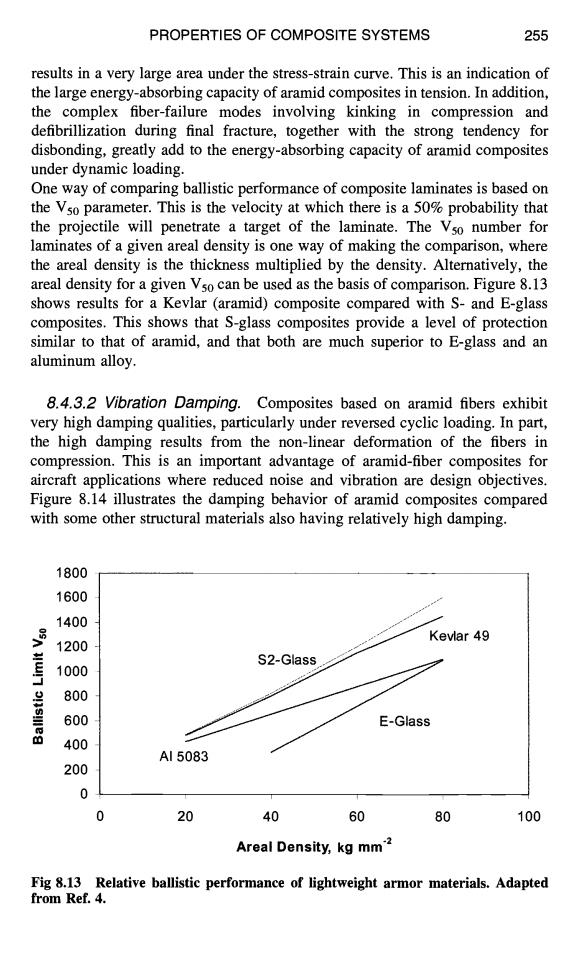

PROPERTIES OF COMPOSITE SYSTEMS 255 results in a very large area under the stress-strain curve.This is an indication of the large energy-absorbing capacity of aramid composites in tension.In addition, the complex fiber-failure modes involving kinking in compression and defibrillization during final fracture,together with the strong tendency for disbonding,greatly add to the energy-absorbing capacity of aramid composites under dynamic loading. One way of comparing ballistic performance of composite laminates is based on the Vso parameter.This is the velocity at which there is a 50%probability that the projectile will penetrate a target of the laminate.The Vso number for laminates of a given areal density is one way of making the comparison,where the areal density is the thickness multiplied by the density.Alternatively,the areal density for a given Vso can be used as the basis of comparison.Figure 8.13 shows results for a Kevlar(aramid)composite compared with S-and E-glass composites.This shows that S-glass composites provide a level of protection similar to that of aramid,and that both are much superior to E-glass and an aluminum alloy. 8.4.3.2 Vibration Damping.Composites based on aramid fibers exhibit very high damping qualities,particularly under reversed cyclic loading.In part, the high damping results from the non-linear deformation of the fibers in compression.This is an important advantage of aramid-fiber composites for aircraft applications where reduced noise and vibration are design objectives. Figure 8.14 illustrates the damping behavior of aramid composites compared with some other structural materials also having relatively high damping. 1800 1600 1400 1200 Kevlar 49 S2-Glass 1000 800 silleg 600 E-Glass 400 A15083 200 0 0 20 40 60 80 100 Areal Density,kg mm2 Fig 8.13 Relative ballistic performance of lightweight armor materials.Adapted from Ref.4

PROPERTIES OF COMPOSITE SYSTEMS 255 results in a very large area under the stress-strain curve. This is an indication of the large energy-absorbing capacity of aramid composites in tension. In addition, the complex fiber-failure modes involving kinking in compression and defibrillization during final fracture, together with the strong tendency for disbonding, greatly add to the energy-absorbing capacity of aramid composites under dynamic loading. One way of comparing ballistic performance of composite laminates is based on the Vso parameter. This is the velocity at which there is a 50% probability that the projectile will penetrate a target of the laminate. The Vso number for laminates of a given areal density is one way of making the comparison, where the areal density is the thickness multiplied by the density. Alternatively, the areal density for a given Vso can be used as the basis of comparison. Figure 8.13 shows results for a Kevlar (aramid) composite compared with S- and E-glass composites. This shows that S-glass composites provide a level of protection similar to that of aramid, and that both are much superior to E-glass and an aluminum alloy. 8.4.3.2 Vibration Damping. Composites based on aramid fibers exhibit very high damping qualities, particularly under reversed cyclic loading. In part, the high damping results from the non-linear deformation of the fibers in compression. This is an important advantage of aramid-fiber composites for aircraft applications where reduced noise and vibration are design objectives. Figure 8.14 illustrates the damping behavior of aramid composites compared with some other structural materials also having relatively high damping. 1800 1600 1400 >~ 1200 .i .~ lOOO u 800 i 600 m m 400 200 /J// ..... ~evlar 49 AI 5083 0 20 40 60 80 100 Areal Density, kg mm "2 Fig 8.13 Relative ballistic performance of lightweight armor materials. Adapted from Ref. 4